Hydraulic Cylinder

The main oil cylinders on both sides adopt electro-hydraulic servo valve and grating scale to form a closed-loop control, with accurate feedback and accurate operation of the slider, so that the bending accuracy and the repeated positioning accuracy of the slider are high.

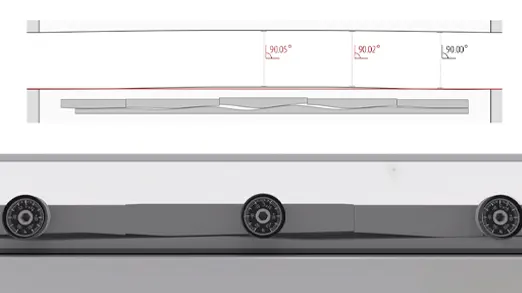

Two-way Mechanical Crowning System

The CNC system automatically calculates and sets the compensation amount, and the compensation adopts closed-loop control with high control precision, which ensures the consistency of the bending angle along the entire length.

The mechanical crowning system is a two-way adjustable structure, which can meet the compensation adjustment of the machine in both transverse and longitudinal directions.

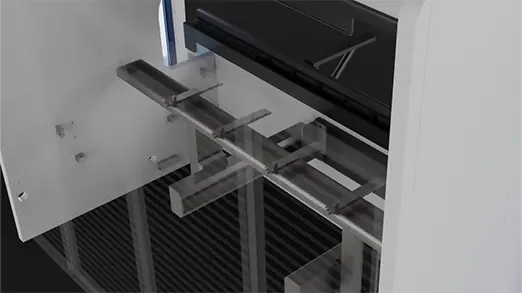

Back Gauge Systems

The back gauge mechanism with complete functions is adopted, and multiple back gauge can be selected and controlled. The functional parts in the back gauge, such as guide rail, ball screw, bearing, etc., all use highnd high-quality accessories to ensure the accuracy of the back gauge.

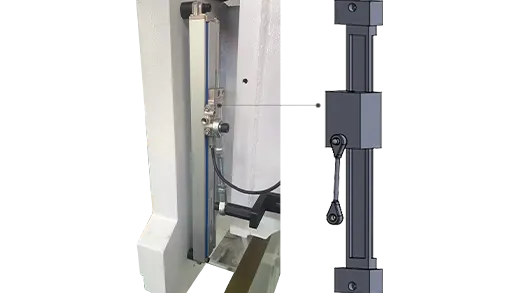

High-accuracy Grating Ruler

C-shaped plates are installed on both sides of the fuselage, and high-precision grating ruler is installed on the C-shaped plate, so as to avoid the influence of fuselage deformation on bending accuracy during bending.

The oil cylinder movement drives the sliding block to move up and down. After the grating ruler can feedback the position of the sliding block to the system, the latter will issue the position adjustment command according to the real-time input data.

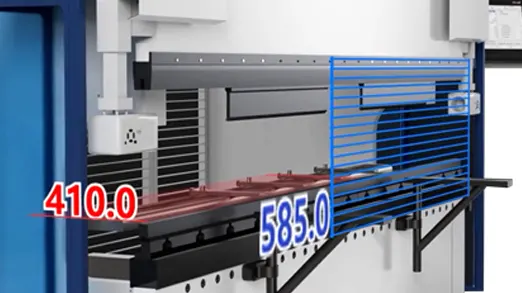

Large Slider Stroke

The slider stroke reaches 235mm, the closing height is 585mm, and with the throat depth of 410mm, the processing scope and the use scope of the mold are expanded. At the same time, the risk of adding machine tools due to workpiece changes shall be minimized

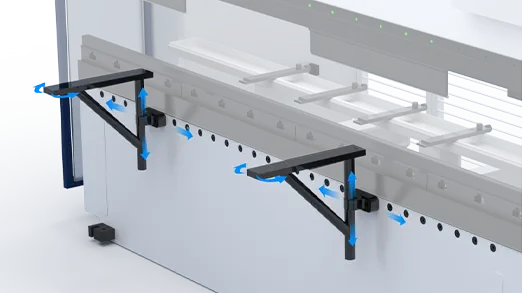

Movable Bracket

The upper part of the workbench is provided with a movable bracket. The bracket can adjust the height and rotation angle as required, adjust the moving position according to the step distance, and assist the bending operation, which is comfortable and efficient.

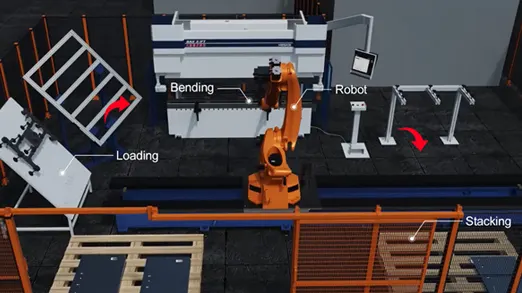

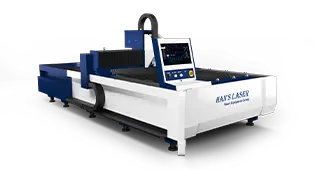

Automatic Bending Cell

Combination of CNC bending machine and robot for automatic gripping, centering, bending and palletizing of plates to meet 24-hour continuous batch production, reducing manual labor intensity, dramatically improving production efficiency and significantly saving costs.Customized bending cell solutions are available upon request.

HBS Series

Press force (kN)

Bending length(mm)

Width between columns(mm)

Throat Depth (mm)

Slide Stroke (mm)

Bed height(mm)

(Rapid Speed)

(Work Speed)

(Return traverse speed)

Main Motor Power (Kw)

Oil Tank Capacity (L)

Dimensions(mm)(Length)

Dimensions(mm)(Width)

Dimensions(mm)(Height)

Machine Weight (kg)

600

1500

1200

215

350

575

200

20

200

6

80

2350

1400

2330

4000

600

2050

1700

215

350

575

200

20

200

6

120

2950

1400

2330

4900

600

2550

2100

215

350

575

200

20

200

6

120

3450

1400

2330

5950

1100

3100

2700

235

410

585

220

17

200

10.8

200

3950

1800

2650

8350

1100

4100

3700

235

410

585

220

17

200

10.8

200

4950

1800

2650

9200

1600

3100

2700

235

410

585

180

14

180

13.2

200

3970

1850

2650

10500

contact us

LET’S TALK

LET’S TALK