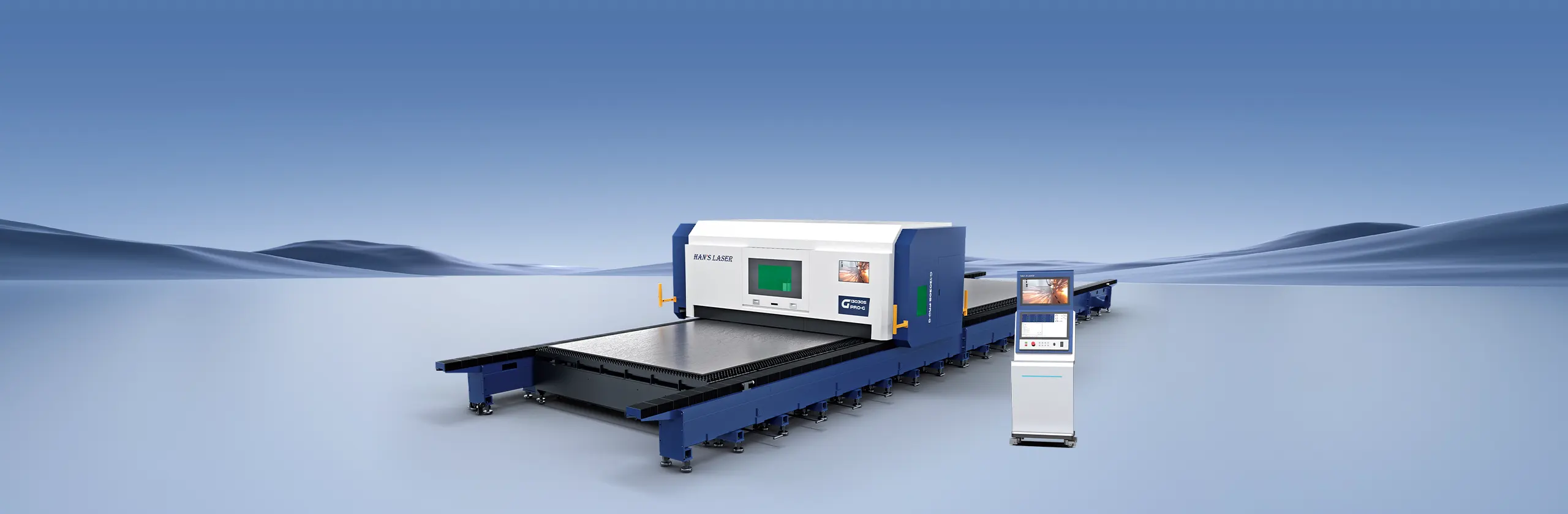

Highest Reliability and Stability

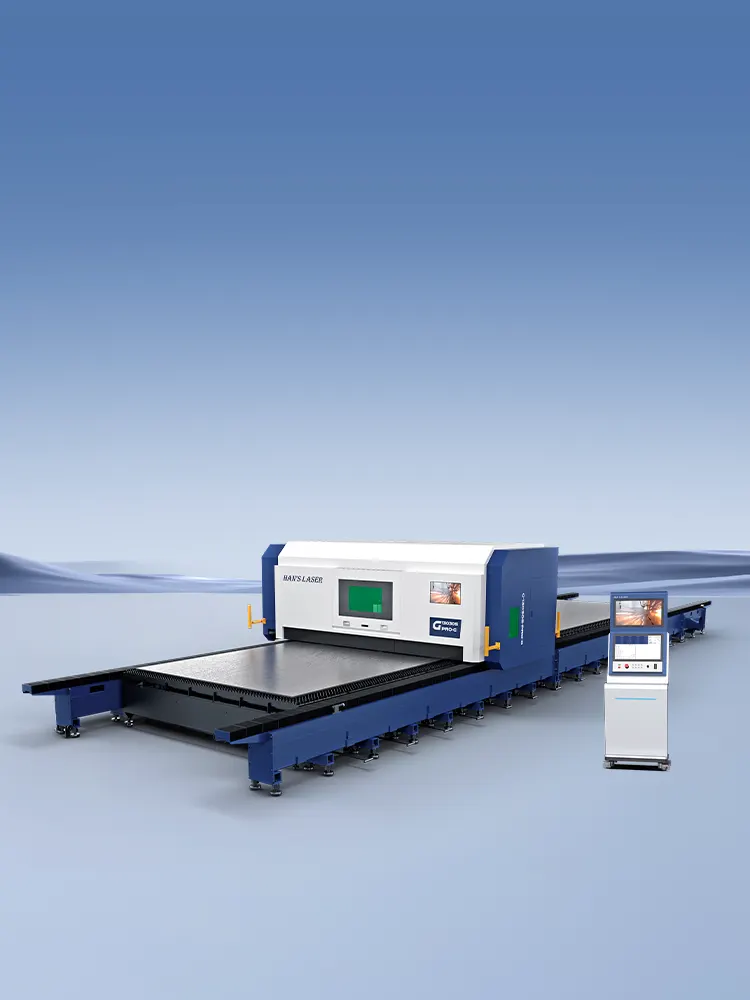

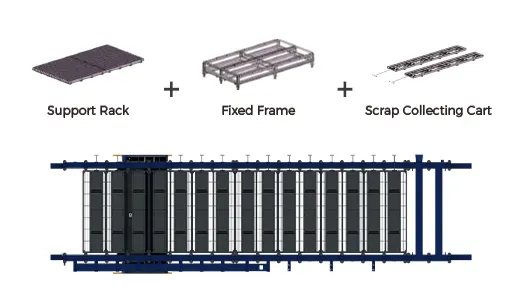

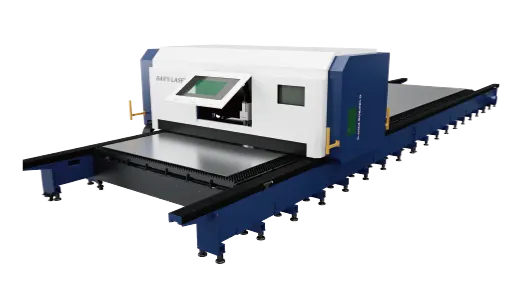

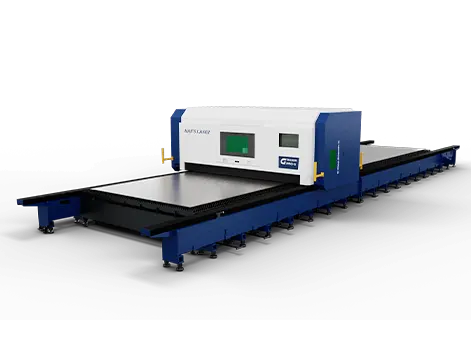

Modular linear rail bed

● The bed and workbench are designed separately avoiding the thermal deformation of the bed;

● Segmeted linear rail bed with compact structure is easy to maintenance and has long service life.

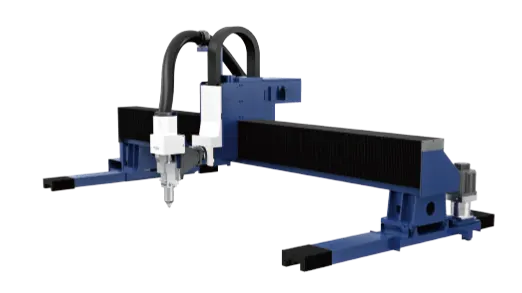

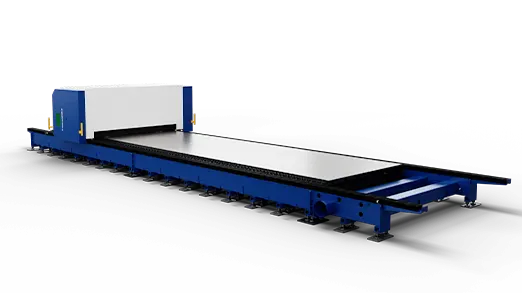

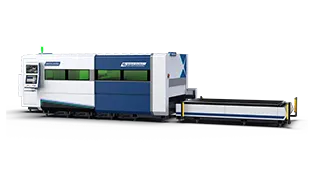

High-Dynamic

Extruded Aluminum Beam

When the format width is below 4m, high-rigidity extruded beam is adopted, optimized by finite element analysis, the inner cavity is designed to effectively disperse internal and external stress, which is lighter and performances better dynamic. The connection between beam and pallet is an adaptive telescopic structure, guaranteeing the long-time cutting stability in different circumstances.

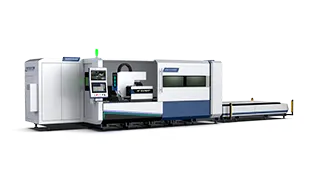

Laser Safety

Gantry cover with OD 5+ laser glass windows:

● Protect the eyes and skin from laser radiation;

● Reduce the noise pollution;

● Reduce the cutting smoke pollution;

● Provide a good working environment;

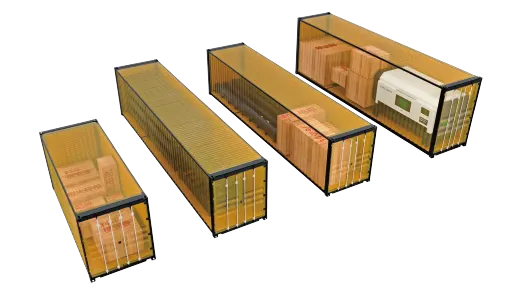

Saving Shipping Costs

Spliced bed design

Work table and machine bed can be loaded into standard containers in sections, while the gantry cover and beam do not need to be disassembled, and can be loaded into the standard containers as a whole, which effectively improves the installation efficiency at the customer's site and greatly facilitates the overseas transportation and installation of the equipment.

Easy to Maintain

Independent unit workbench.

Independent foot support, which is completely separated form the bed, to solve the impact of medium-thickness plate loading on the bed. Easy to disassemble and maintenance with low cost of use.

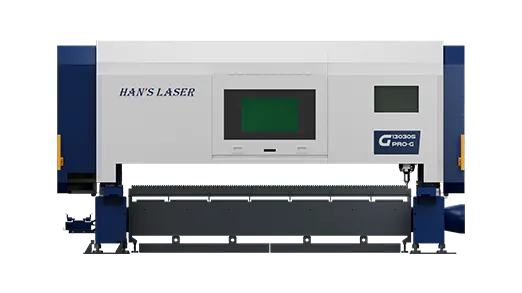

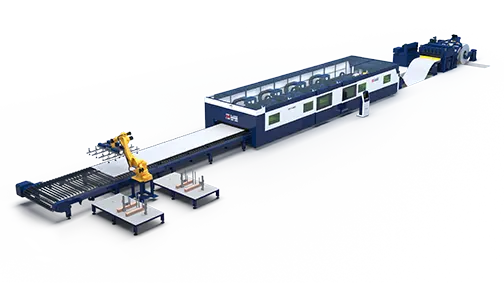

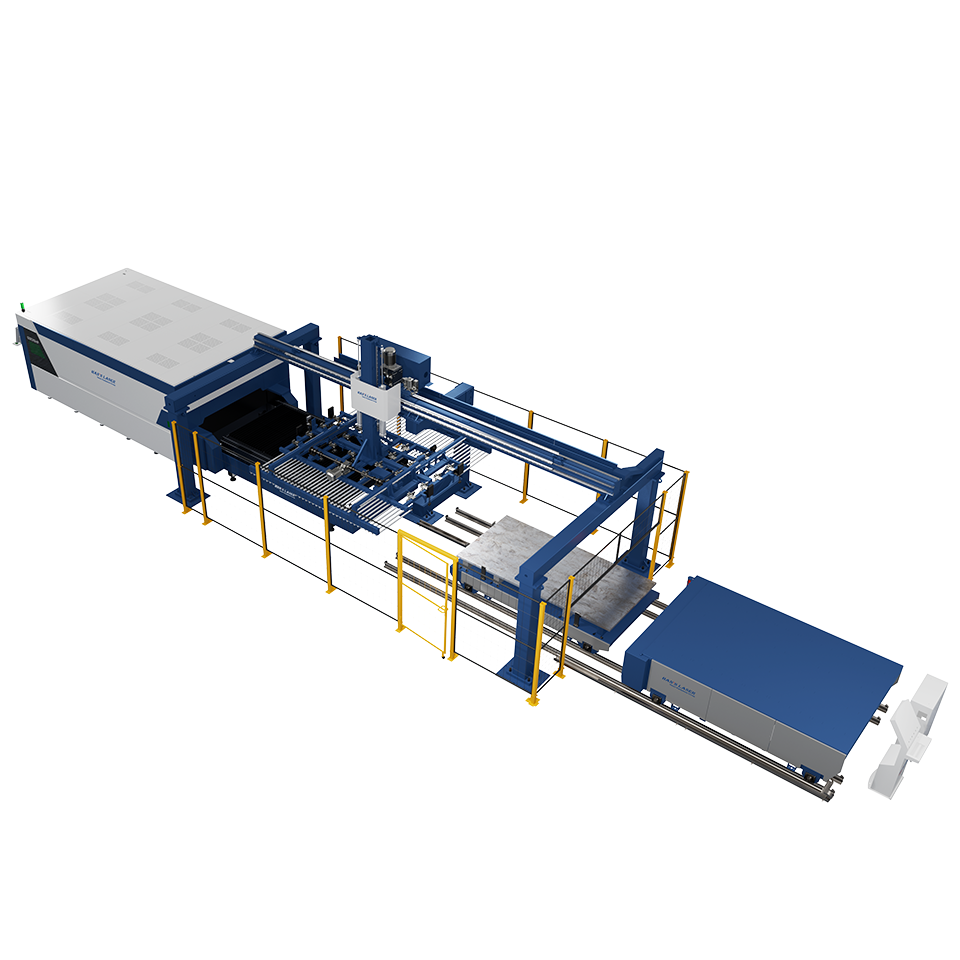

Ultra-large Format

Suitable for large format and thick plate cutting.

With a large processing width of 13mx3m, the processing width size can be selected from 3m, 3.5m ⁄ 4m, and the length can be extended to 15m ⁄ 26m ⁄ 30m or even longer, and it can withstand ultra-high power laser cutting of more than 60kW, which can easily satisfy the needs of the steel structure, shipbuilding, heavy industry and other industries for large format and thick plate cutting.

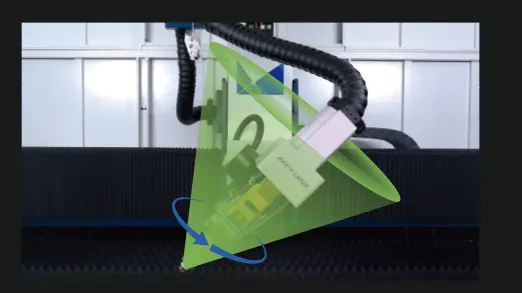

Vertical / Bevel Cut is Available

Han's self-research swinging head structure

Lightweight design and high dynamic performance. For bevel cutting, algorithms and functions such as bevel follower algorithm, bevel tool compensation algorithm, bevel pendulum bias algorithm bevel vertical automatic detection, bevel vertical automatic reset and other algorithms and functions have been developed to meet the needs of bevel processing in various industries.

Intuitively Machine Operation

Operator's console with monitor screen

Real-time monitoring inside the machine tool, so that operators know the cutting process at a glance, while equipped with a 32-key hand-held box to make the equipment running the necessary quick operation at a glance, greatly simplifying the operating procedures, to provide a strong guarantee for efficient production.

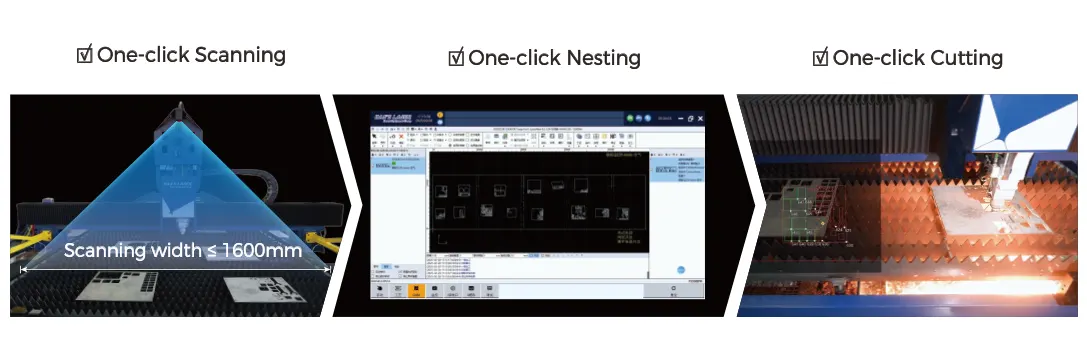

Use Remainder Sheets

Intelligent remnant material processing solution based on automated vision inspection technology to position any number of part geometries on the remainder sheet. Remnant processing area achieves full worktable coverage, supports multi-plate simultaneous scanning with one-time accurate remnant contour recognition, revolutionizing traditional inefficient remnant methods with rapid production optimization and cost-effective material usage.

S Pro - A(Straight)/G(Bevel)

Working Area

Max. Axis positioning speed (X/Y)

Precision

Repetitiveness

Max. sheet weight

Available laser power

6100mmx2600mm

80m/min

0.05mm/m

0.03mm/m

7200kg/table

8100mmx2600mm

80m/min

0.05mm/m

0.03mm/m

9600kg/table

13100mmx2600mm

80m/min

0.05mm/m

0.03mm/m

15600kg/table

12kW/20kW/30kW/40kW/60kW

26100mmx2600mm

80m/min

0.05mm/m

0.03mm/m

31200kg/table

30100mmx2600mm

80m/min

0.05mm/m

0.03mm/m

36000kg/table

contact us

LET’S TALK

LET’S TALK