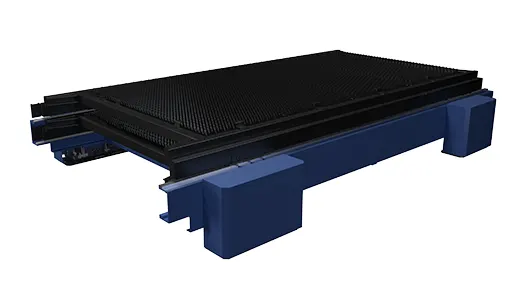

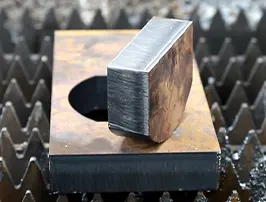

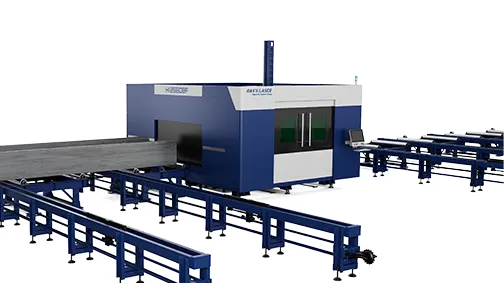

Heavy Load Capacity for Thick Material

The synchronous lifting precision can achieve ±1%

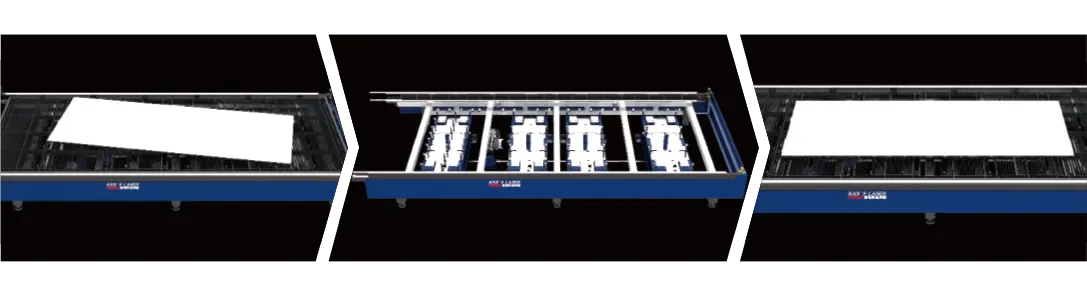

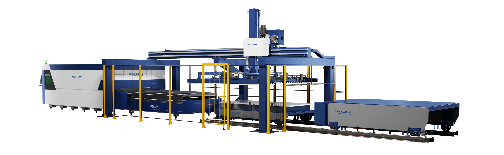

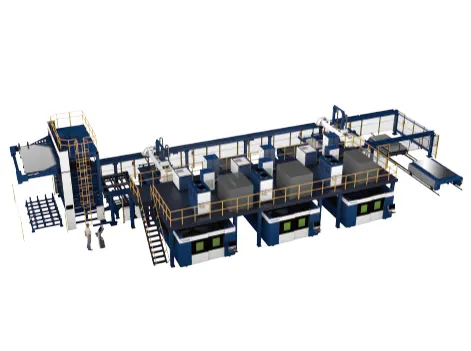

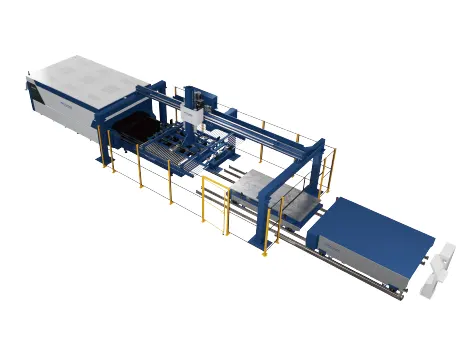

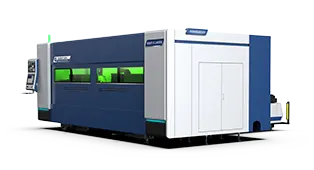

● Two tables can pull out of cutting area at the same time;

● Loading & unloading on the table does not affect the other;

● Easy to do maintains job in side the machine,fast and safe loading and unloading of the metal sheets;

● Ensure good cutting quality when the other table is loading or unloading;

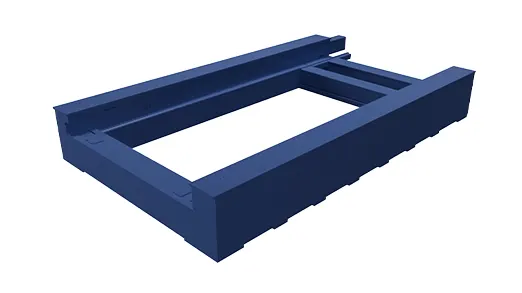

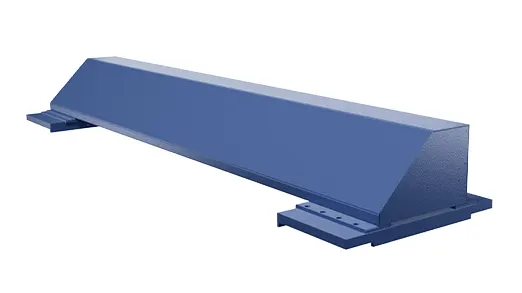

The Long-term Reliability

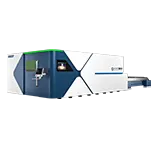

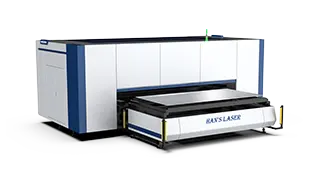

New hollow structure

● Avoid the risk of high power heat deformation;

● Conveyor as an optional can be easily added to HF50;

● Suitable for laser power Up to 50kW;

● The machine bed and worktable are separate;

● Ensure the long-term stability of the Machine.

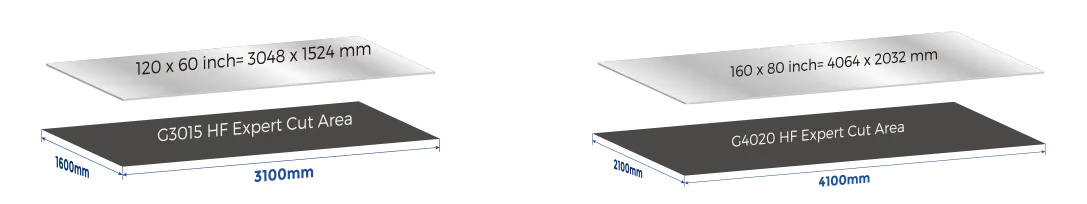

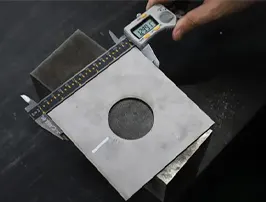

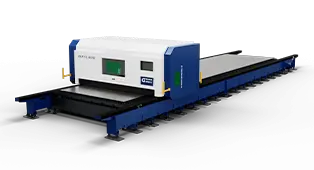

Larger Cutting Area

Increased cutting area,be able to cut AS (American standard) sheet in “inch” size.

More Parts Output

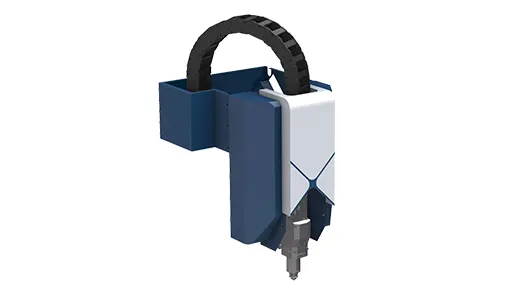

New Z-axis using linear drive system with automatic lubrication device. Linear guide equipped with integrated measuring system & adjusting blocks, faster positioning speed and higher acceleration, longer service life and higher cutting accuracy.

High Dynamic Patented Design

New gantry with self-adjustment flexible gantry

● The maximum speed of single axis can reach 300mm/min;

● The Max. acceleration can reach 5g;

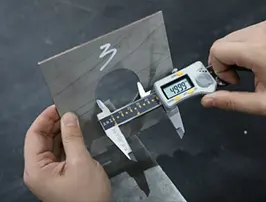

● The positioning precision can achieve 0.01

● Repetitiveness can achieve 0.005mm;

Anti-scratch

Plate lifting and adjusting device(Optional)

● Anti-scratch the underside of the sheet; ● Easy to load and adjust the plate ;

● Ensure a good cut quality especially for stainless steel and aluminum.

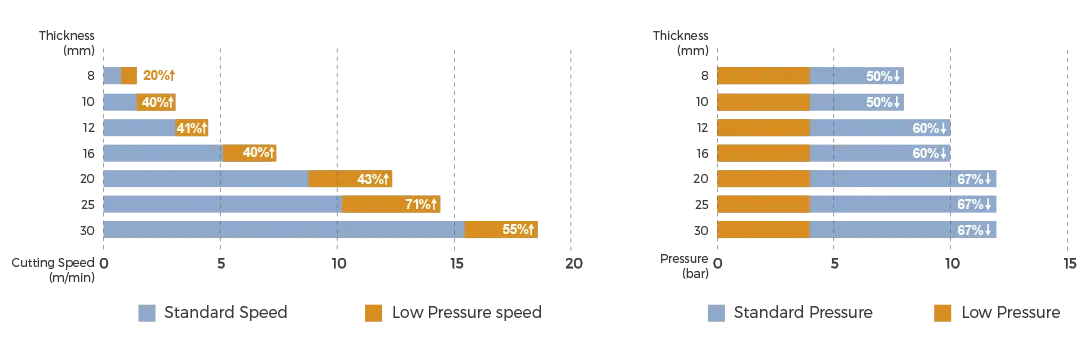

Lower Gas Consumption

Low N2 pressure cut

Faster cutting speed,less cutting time of the same batch, up to 67% Gas Saving.

Mix-M Device

Gas mixing cabinet patent of Han's Laser (Optional)

Mix-M process function: equipped with a 20kW or higher power laser, suitable for rapid cutting of 10~40mm carbon steel, solving the problem of traditional medium and thick plate cutting sections and corner slag hanging, effectively improving the upper and lower taper and roughness of the workpiece, greatly improving processing efficiency and workpiece accuracy.

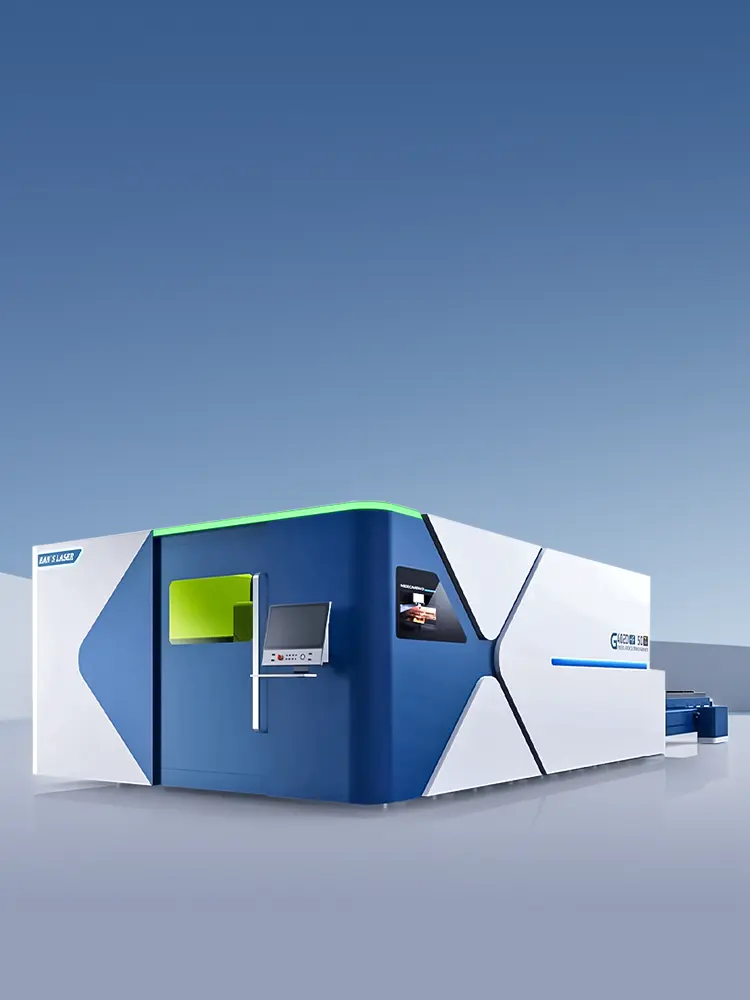

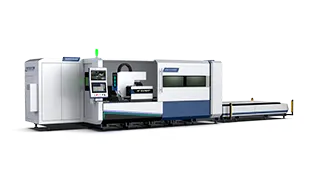

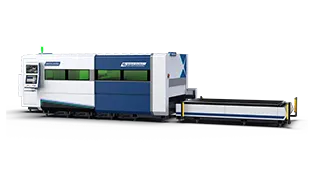

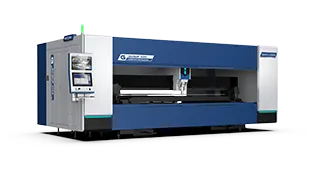

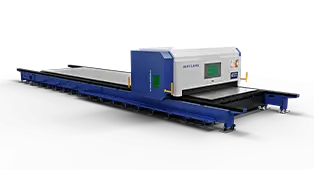

HF 50 Series

Working Area [mm]

Max. Axis positioning speed (X/Y)

Max.Acceleration

Precision

Repetitiveness

Max.sheet weight

3100mmx1600mm

300m/min

5g

0.01mm

0.005m/min

2150kg/table

4100mmx2100mm

300m/min

5g

0.01mm

0.005m/min

3840kg/table

4100mmx2600mm

300m/min

5g

0.01mm

0.005m/min

4680kg/table

contact us

LET’S TALK

LET’S TALK