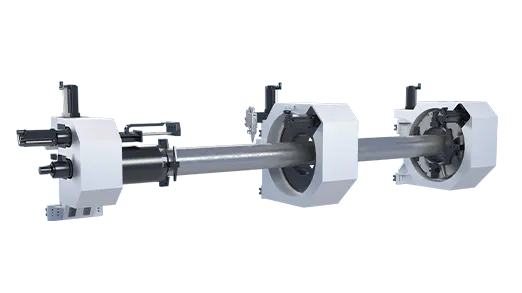

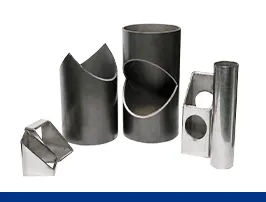

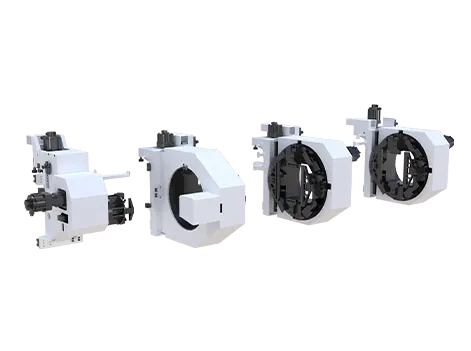

Zero Scrap

The cutting head can cross the center chuck and cut in the other direction, realizing really zero scrap .Full-process integrated chuck, the center chuck and the unloading chuck are integrated chucks, switching between large and small tubes without jaws change.

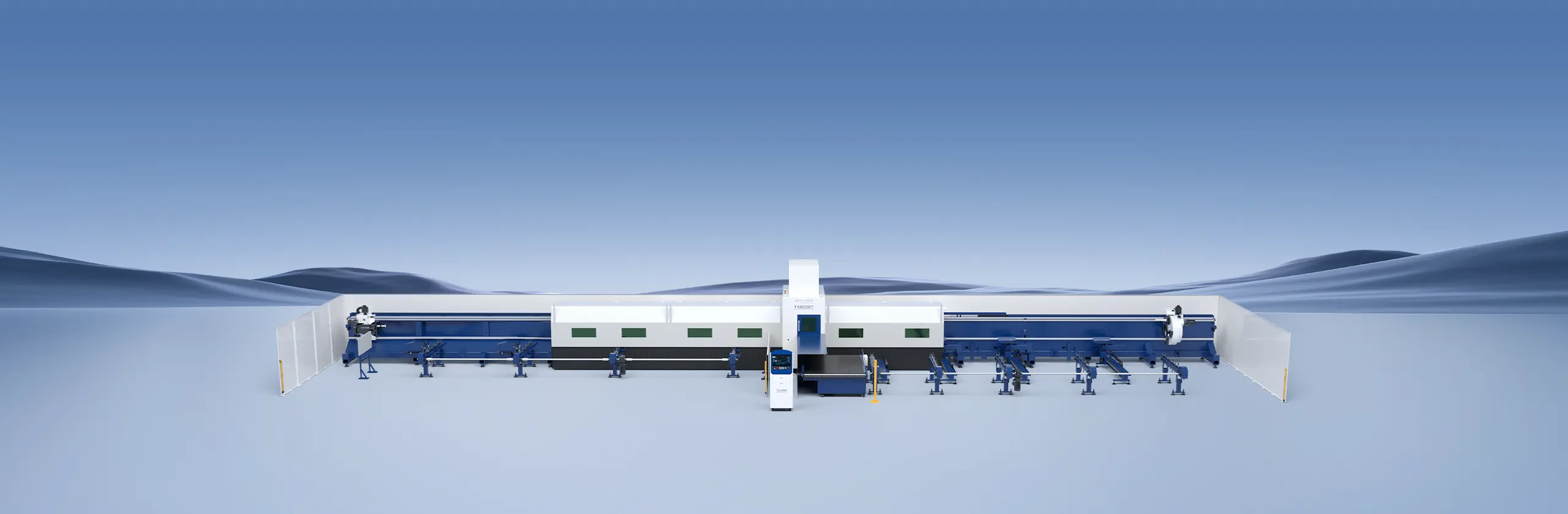

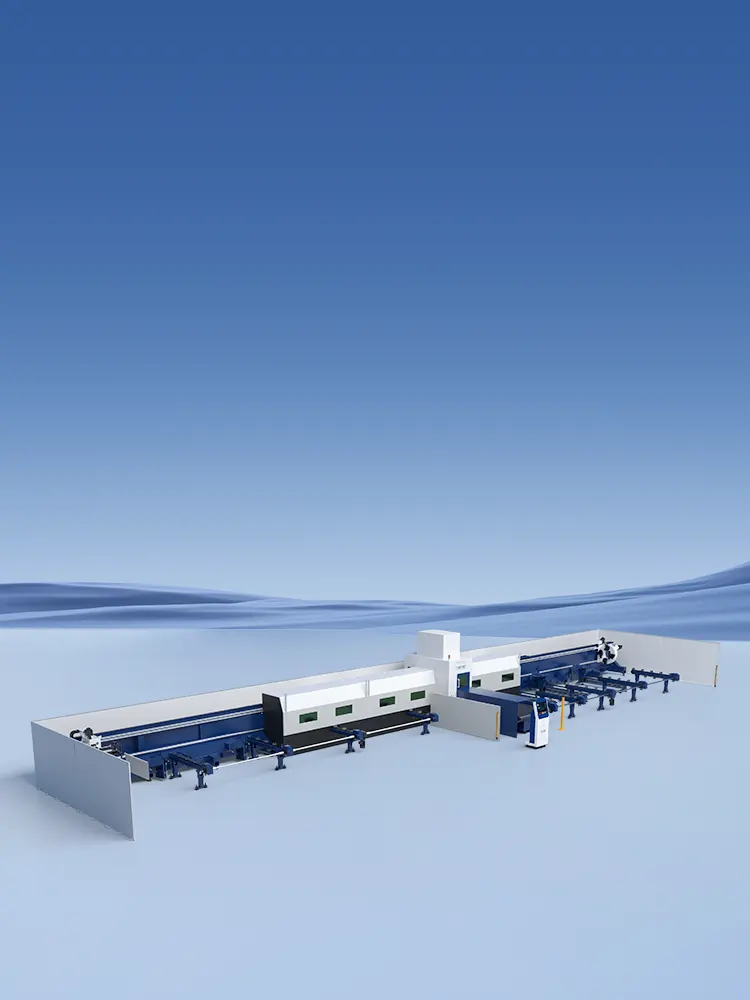

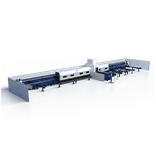

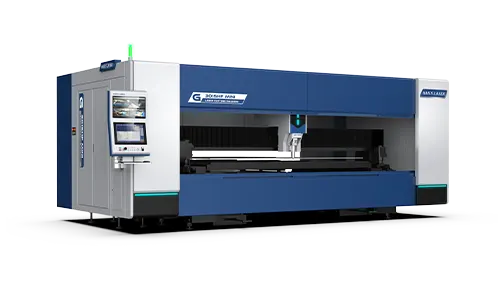

Side-mounted Bed

Strong rigidity, stable and reliable structure, supports loading, cutting and unloading of 12m tube, that can keep the precision of the machine tool for a long time, and adopts precision rack and pinion, roller linear guideway to ensure the precision of transmission effectively.

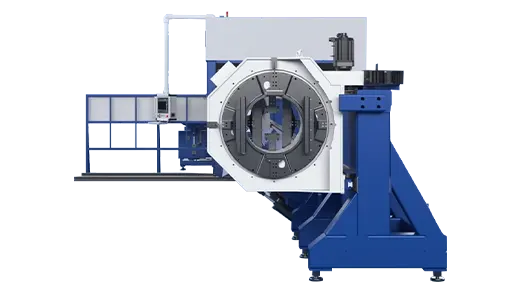

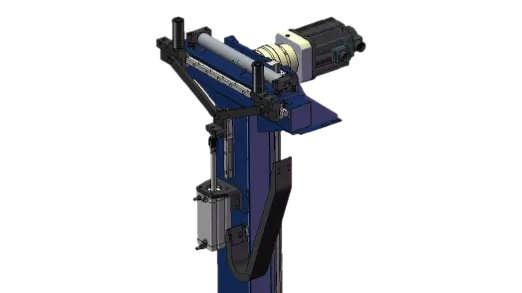

Follower-assisted Support

Equipped with centering function, the support device always follows the pipe material Rotate and float up and down to ensure effective support and prevent pipe sagging.

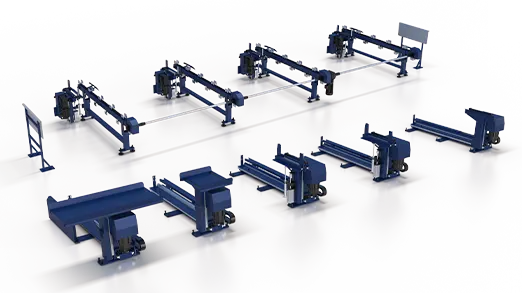

Loading and Unloading Device

Semi-automatic structure of loading and unloading as standard configuration, simple and convenient loading with high efficiency. 4 sets of floating unloading pallets for auxiliary support to improved processing accuracy.

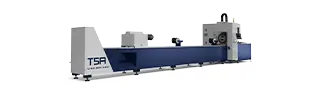

TX Series

Processing range

Positioning accuracy (X/Y)

Repeatability (X/Y)

Max.Speed

Max. Positioning Speed(A/B/C)

Processing range

Unloading length

Length of leftover materials

Max.Tube weight

Ф40-360mm □40-350mm

±0.05mm/1000mm

±0.05mm

60m/min

80r/min

0-6000/0-12000mm

≥0

1200kg(≤100kg/m)

Ф50-500mm □50-500mm

±0.05mm/1000mm

±0.05mm

60m/min

40r/min

5800-6200mm 8800-9200mm 11800-12100mm

0-6000/0-12000mm

≥0

2000kg(≤167kg/m)

12000mmxФ80-660mm 12000mmxФ80-450mm

±0.01mm/1000mm

±0.01mm

40m/min

30r/min

0-12000mm

≥0

2500kg(≤167kg/m)

contact us

LET’S TALK

LET’S TALK