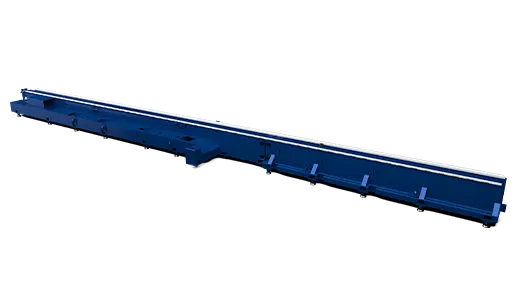

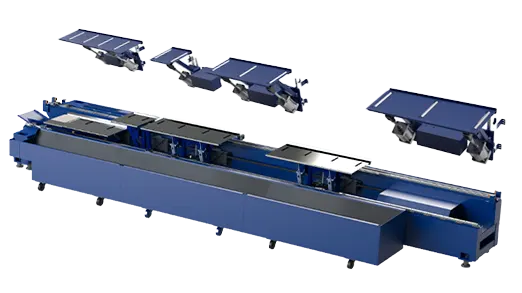

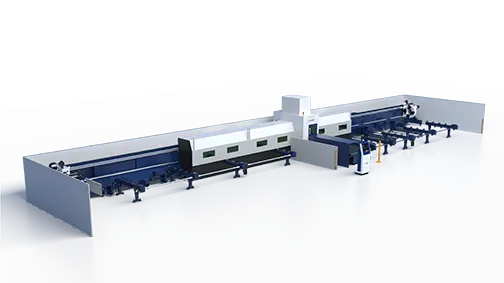

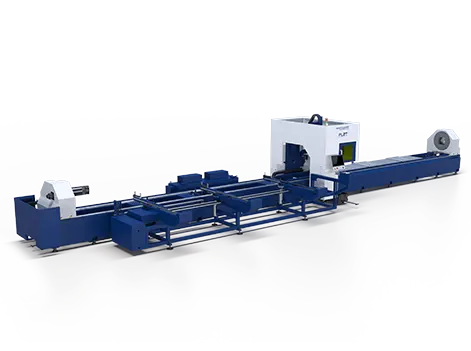

Horizontal Bed Structure

Horizontal configuration with high-precision linear guide rails ensure smooth efficient transmission and robust load-bearing capacity.

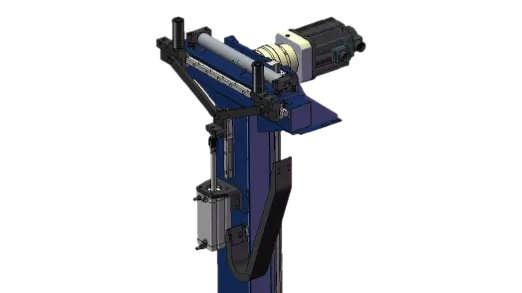

Precision Chucks

Equipped with a precision transmission system to prevent contamination and maintain transmission accuracy.

Triple-chuck system with the second and third chucks feature full-stroke capability, eliminating gear adjustments when switching between large and small tubes.

Floating Support

Support units dynamically adjust to the tube's rotational radius, Independent servo motor control, fast response and high load capacity, ensuring stable positioning and enhanced machining precision.

Floating Support System

Fixed unloading with buffer and tilt-slide function, equipped with vision-guided recognition system for precise identification and rapid sorting of various workpieces. 6m floating unloading system with high load-bearing capacity easily handling tubes over 300kg.

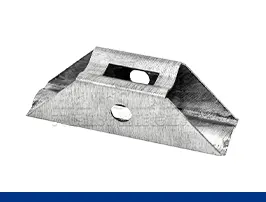

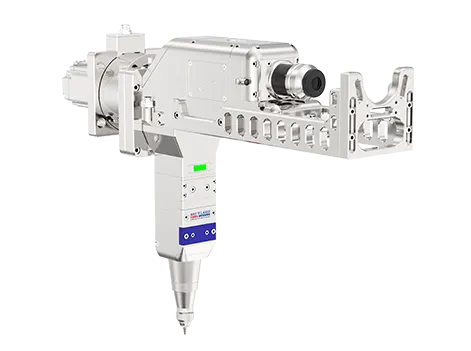

Zero Scrap

The cutting head can cross the center chuck and cut in the other direction, realizing really zero scrap, improving material utilization.

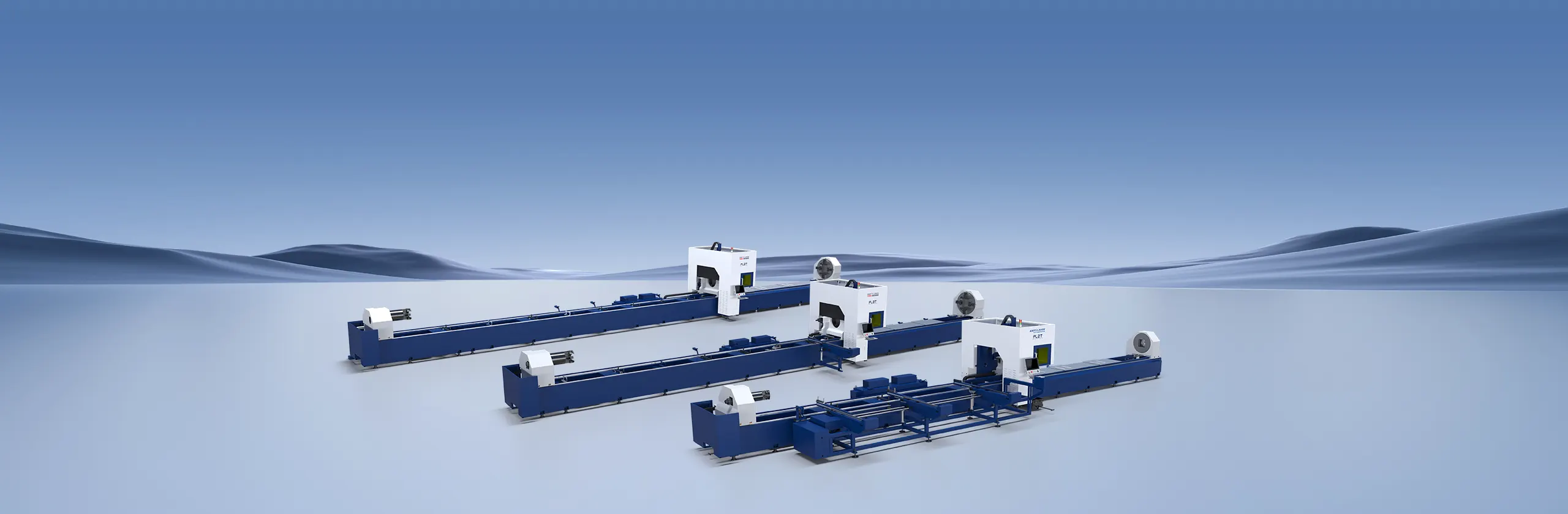

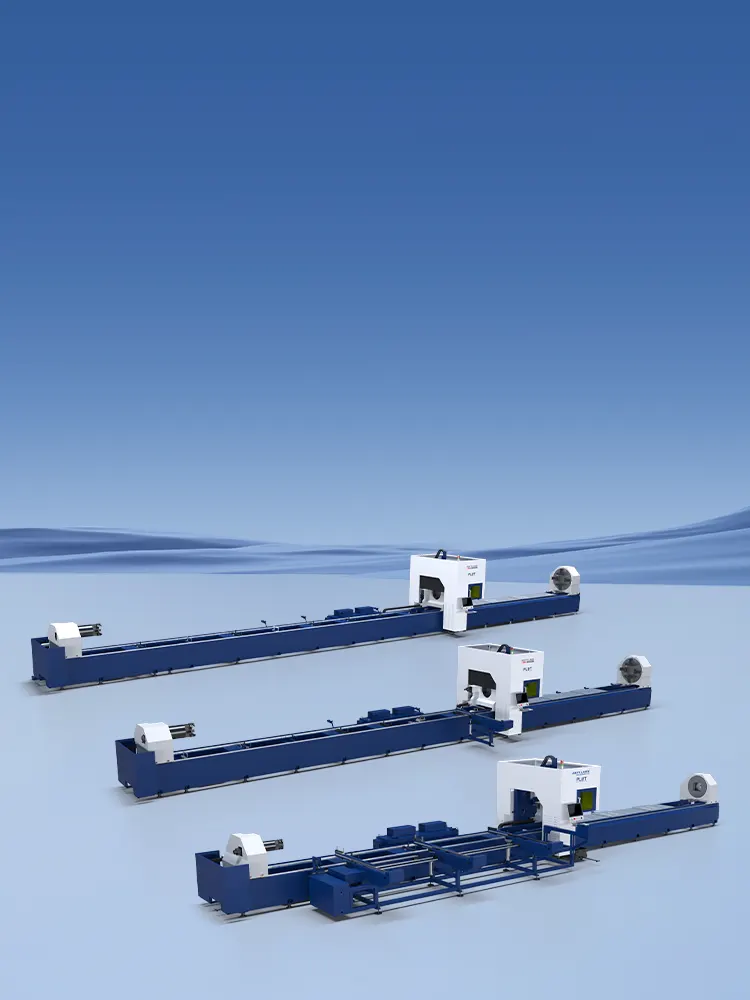

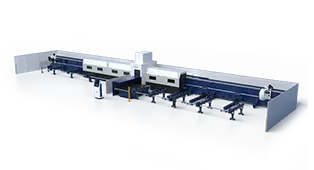

PLT Series

Round Tube Diameter

Square Tube Side Length

Positioning accuracy (X/Y)

Repeatability (X/Y)

Max. Positioning Speed(X/Y)

Max. Positioning Speed(A/B/C)

Max. Loading Length

Unloading length

Max. Tube Weight

φ20-240mm

□20-240mm

±0.05mm/1000mm

±0.05mm

100m/min

100rpm

6200mm

0-6000mm

300kg

φ20-240mm

□20-240mm

±0.05mm/1000mm

±0.05mm

100m/min

100rpm

9200mm

0-9000mm

300kg

φ20-360mm

□20-350mm

±0.05mm/1000mm

±0.05mm

80m/min

80rpm

6200mm

0-6000mm

500kg

φ20-360mm

□20-350mm

±0.05mm/1000mm

±0.05mm

80m/min

80rpm

9200mm

0-9000mm

600kg

φ20-360mm

□20-350mm

±0.05mm/1000mm

±0.05mm

80m/min

80rpm

12200mm

0-12000mm

850kg

contact us

LET’S TALK

LET’S TALK