Unmatched Productivity

Shorter processing time with increased through put.

Thanks to top-quality transmission device, the C3 PRO reaches high speed and high acceleration, which means more parts or output in the same amount of time.

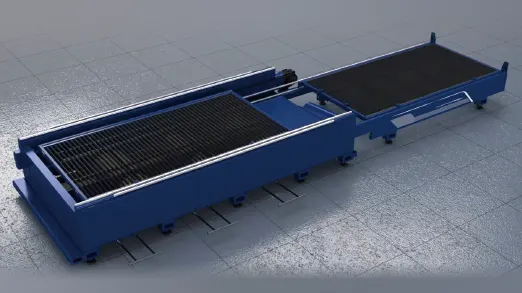

More Flexible

Interactive workbench <25″

● Two tables can pull out of cutting area at the same time;

● Easy to do maintains job inside the machine;

● Loading & unloading on the table does not affect the other;

● Ensure good cutting quality when the other table is loading or unloading;

Exceptional Dynamic Performance

High-Strength Lightweight Gantry

● Enhanced dynamic performance with over 30% acceleration improvement;

● The maximum linkage speed of the X ⁄ Y axis is 160 m/min, with an acceleration of 2.0g;

High Stability

Reinforced Bed Structure Design

The high-rigidity machine bed is treated with high-temperature stress relief treatment. Its robust and vibration-resistant construction delivers exceptional precision, minimal vibration, and extended service life for laser cutting operations.

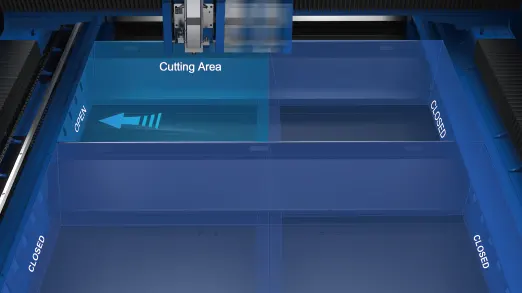

Work Environment Friendly

Matrix-Type Adaptive Dust Extraction

High-capacity filtration system with dynamic control of the exhaust port, shortened airflow path, concentrated wind force, and powerful suction for efficient fume and particulate removal. It also reliable to reduce the risk of contamination of the cutting head and keep your working area clean.

Burn-Free Edges

Smart Corner Processing

Dynamic parameter adjustment and optimized path algorithms ensure smooth transitions between right, acute and obtuse angles with clean, burr-free cuts.

Easy to Operate

Excellent Performance Bus Control System

● High cutting efficiency, excellent cutting quality, precise control, and user-friendly operation;

● Supports one-click quick import of drawings in formats such as DWG, DXF, and LXDS;

● MES docking is easy to realize, allowing real-time equipment operation monitoring and task updates via a mobile phone application.

High-precision

Dual-Drive Precision Gear Reducers with Rack-and-Pinion System.

Professional manufacturing process equipped with high-precision core transmission components, small friction coefficient, high positioning accuracy, high sensitivity, low noise when operating at high speed, long-term life time of components, and good dimensional accuracy of parts.

Improve Part Quality

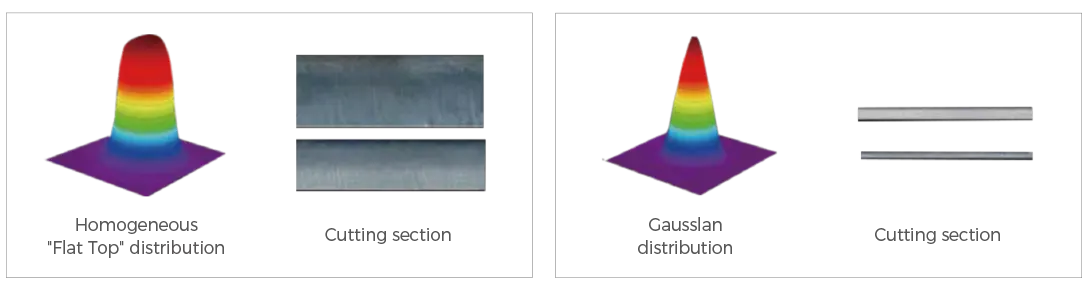

Variable Beam Shape

The beam pattern can be switched at any time for different plates, advanced in cutting both thick and thin plates, doubling the efficiency.

● Circular spot: Oxygen cutting is more stable, heat is more dispersed, and the average;

● Gaussian spot: Air/nitrogen cutting speed is faster, heat is concentrated;

● Double spot is mainly aimed at cutting medium and thick plates, improving cutting speed and cutting section quality.

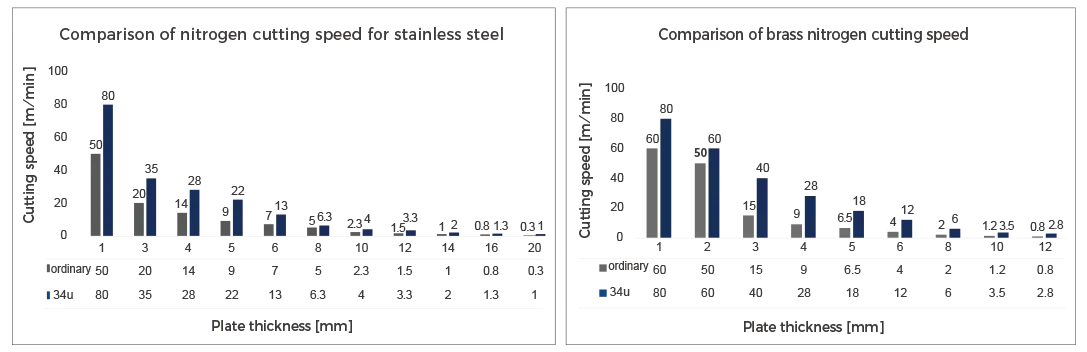

More Efficient Cutting

Even Handle Highly Reflective Materials

The laser power is continuously adjustable, with high beam quality and reduced spot diameter, enabling micron-level cutting to meet high-precision requirements. It can perform high-speed cutting on various plates such as carbon steel, stainless steel, aluminum, brass, etc; The air cutting speed and nitrogen cutting speed are greatly improved, and the production efficiency is significantly improved;

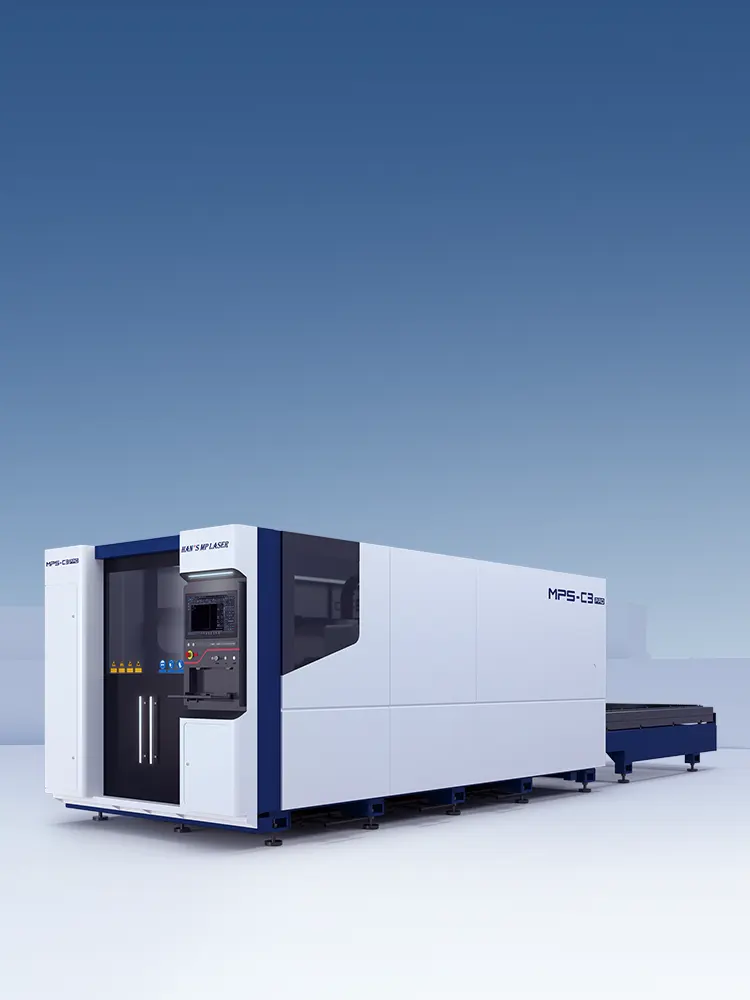

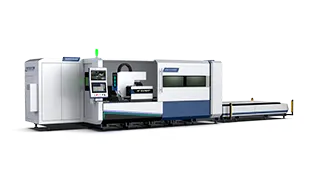

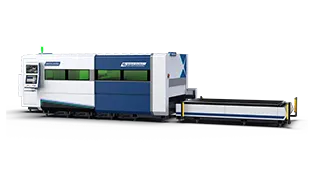

MPS-C3 PRO

Working Area

Max. Axis positioning speed (X/Y)

Max. Acceleration

Repetitiveness

Available laser power

3200mmx1500mm

≤160m/min

≤2.0g

±0.03mm

3000W ⁄ 6000W

contact us

LET’S TALK

LET’S TALK