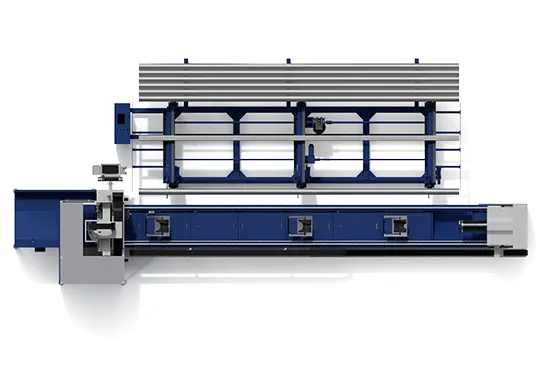

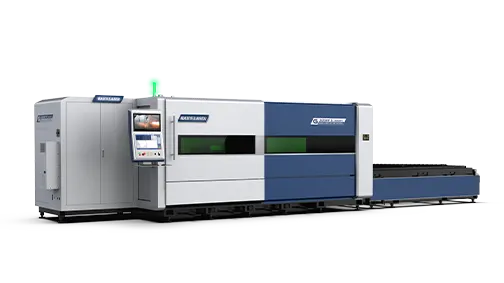

High Strength Heavy Duty Welded Machine Bed

The entire machine is welded and formed from profiles, and then processed after heat treatment and annealing. The excellent heat treatment process ensures the overall rigidity of the machine tool and the stability of long-term use.

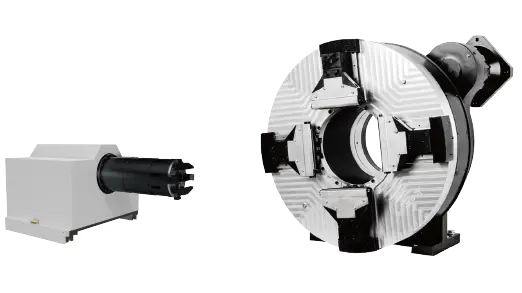

Linkage Self Centering Chuck

Both the front and rear adopt a two pair linkage self centering chuck, with pneumatic automatic clamping working mode, which are suitable for clamping round tubes, square tubes, rectangular tubes, I-beams and various symmetrical special-shaped tubes.

Integrated CNC Forming Chuck

The chuck adopts overall protection to ensure no dust or waste enters the interior. The sliding block moves with precision, and the moving parts are hardened and wear-resistant, with guaranteed accuracy control. The double roller gripper has a reasonable support span and strong rigidity, ensuring stable clamping during rotation and processing accuracy.

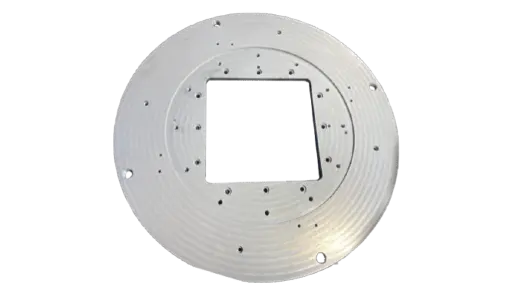

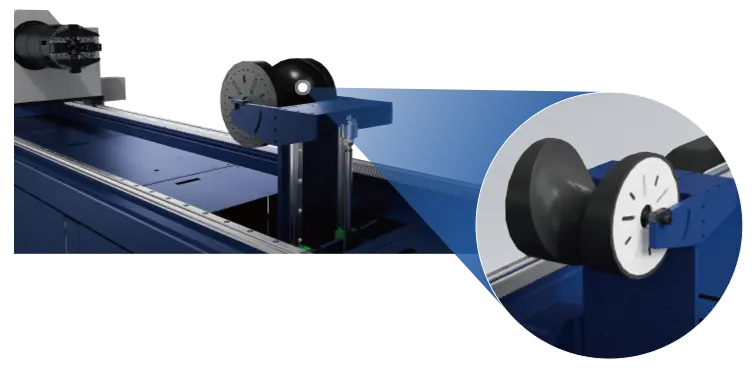

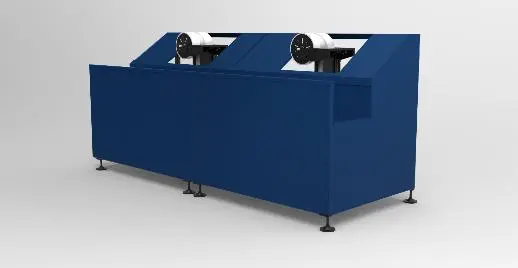

Variable Diameter Wheel Supports Loading

It is used to feed raw materials and support long workpieces during the profile processing , replacing manual feeding.

The feeding is more stable, reducing the vibration of high-speed rotation of pipes to make cutting more accurate, reducing the sinking amplitude of pipes to improve the linear straightness of pipes and prevent pipes from shaking.

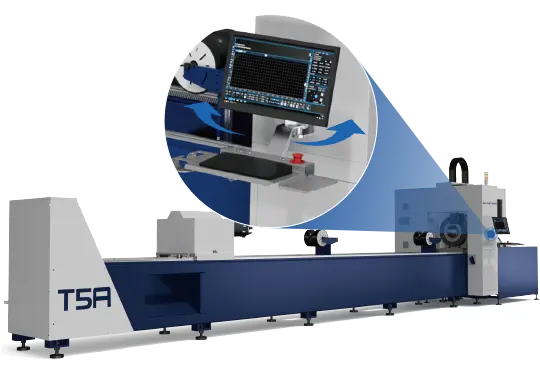

User-friendly Operation Interface

The equipment is stable, with a user-friendly operation interface, real-time feedback of processing status, fully enclosed protection of the cutting area, equipped with safety doors and visual windows to ensure the orderly progress of cutting processing.

Frog Jumping Cutting

Support frog jumping cutting, reducing the idle running time of the machine tool and improving cutting efficiency. Each perforation point saves 0.3 seconds of time.

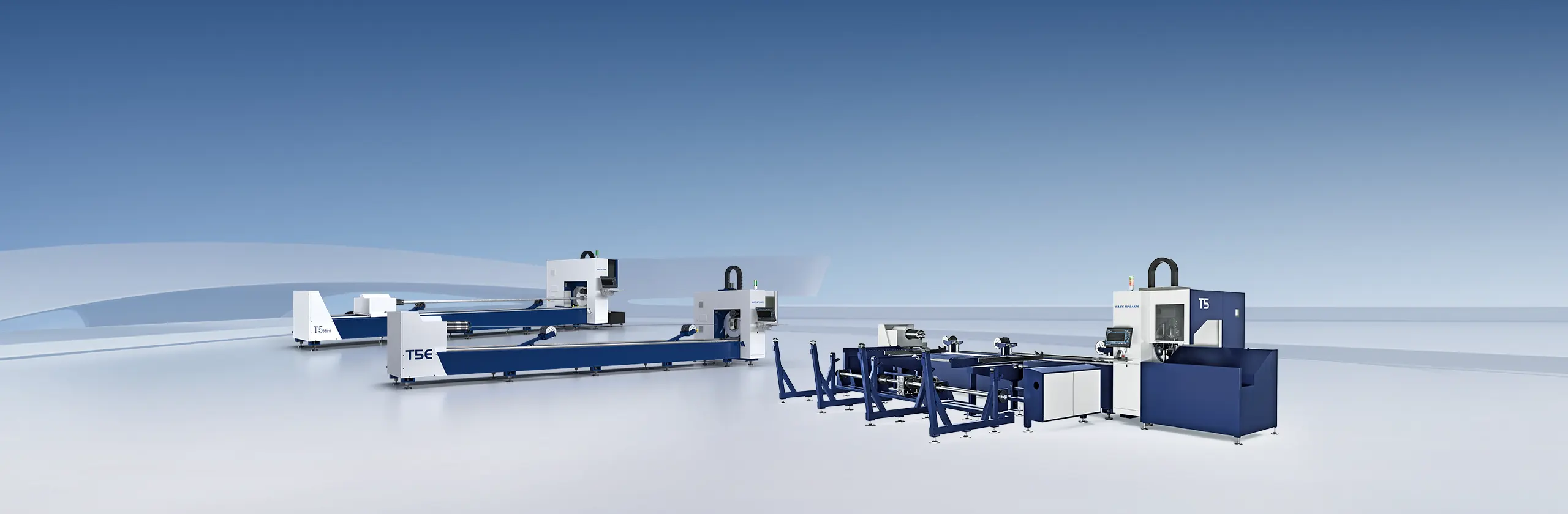

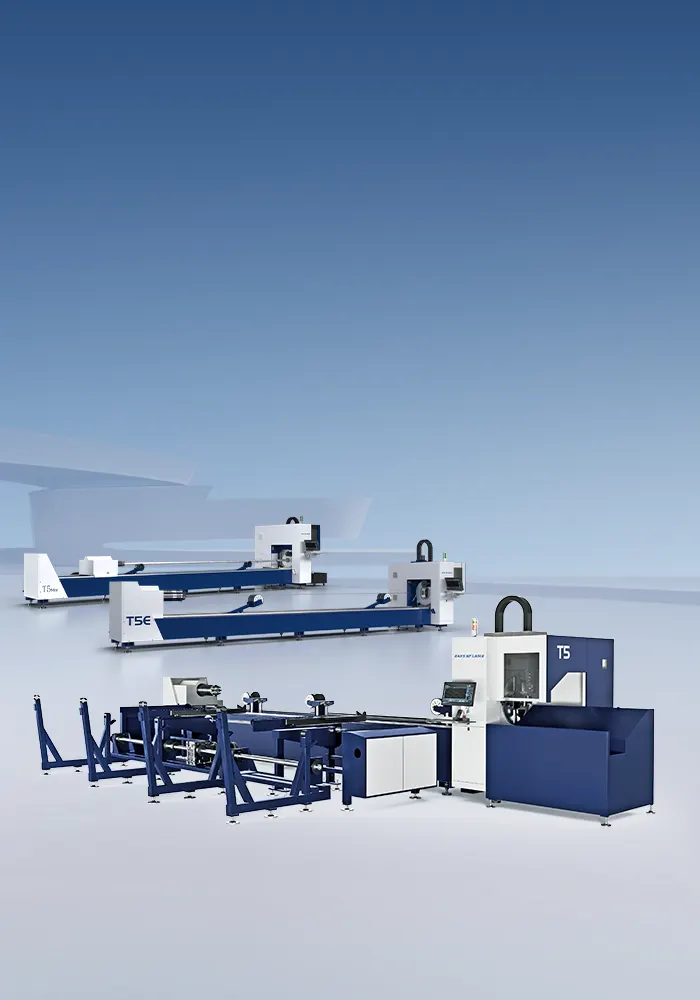

T5 Series

Max processable pipe length

Maximum speed

Max operating acceleration

Max load capacity (single)

Tail material length

Range of material wall thickness

Processing capacity

≤6500mm

T5mini: 200R/min

1.0g

260kg(≤43kg/m)

≥80mm

≥0.8mm

H Beam≤8#

≤6500mm

T5: 120R/min

1.0g

260kg(≤43kg/m)

≥80mm

≥0.8mm

H Beam≤20#

contact us

LET’S TALK

LET’S TALK