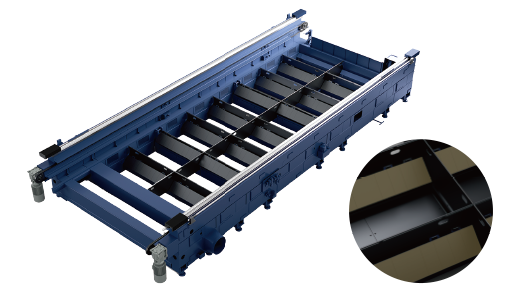

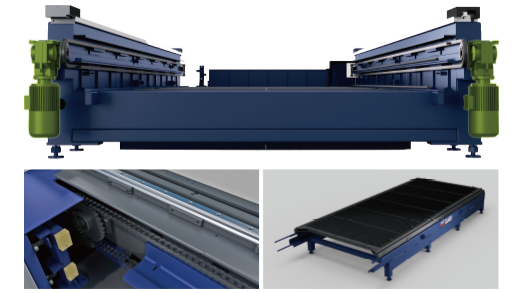

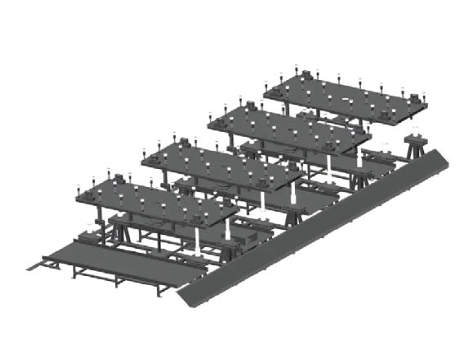

Semi-hollow Structure Machine Bed

The frame base is welded and formed by carbon steel, and then processed by annealing, rough machining, vibration aging, finishing and other processes to achieve its rigid and robust features.

The specific semi-hollow structure truly avoids the risk of the bed deformation caused by high power heating, which meets the requirements of 50kW ultra-high power laser cutting.

In addition, refractory bricks have been laid above the frame. These refractory bricks are an additional barrier to high power laser cutting and are easy and inexpensive to maintain.

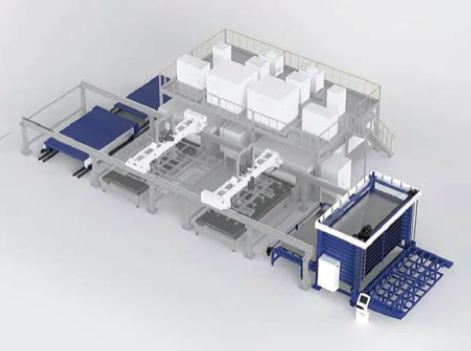

Multi-zone Suction System

The multi-zone suction comes with good dust removal effect by area, which intelligently distributes the air volume of each exhaust outlet to each partition structure and effectively improve the suction and dust removal capacity of the processing area. It also reliable to reduce the risk of contamination of the cutting head that keep your working area clean.

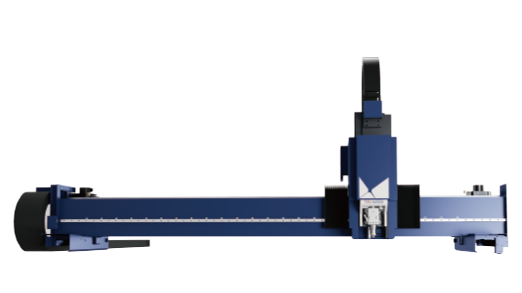

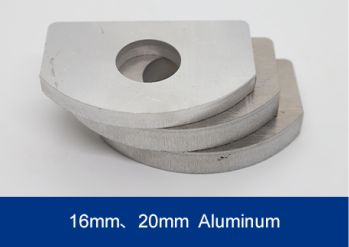

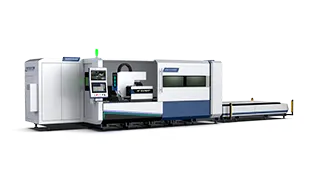

New Gantry with Extruded Aluminum

Lighter, stronger, better looking and shorter lead time.

● Z-axis gear rack structure, impact resistance and pollution resistance.

● The guide slide structure prevents the guide assembly from changing accuracy due to collision with the cutting head;

● The automatic lubrication device avoids oil-free friction movement, improves the service life of machine transmission components, and ensures stable machine operation speed and accuracy.

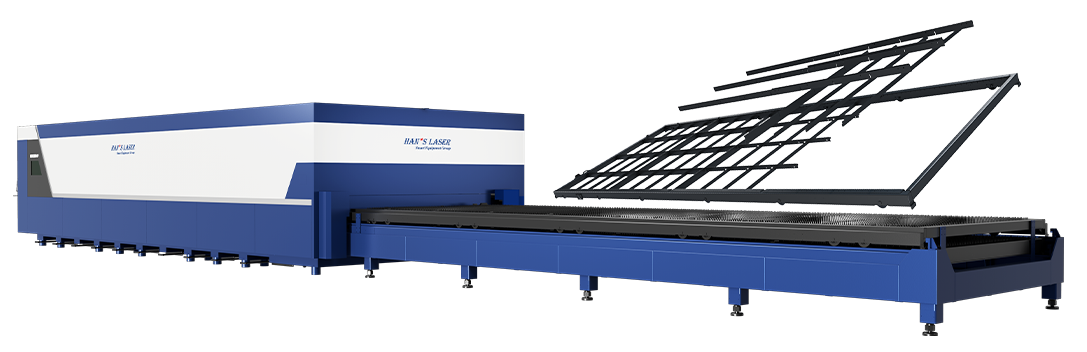

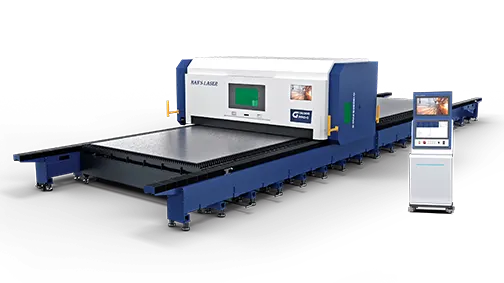

Shuttle Table with Double Drive System

● Using high-tensile strength chain, two tables can pull out of cutting area at the same time.

● Loading and unloading on the table does not affect the other, ensure good cutting quality when the other table is loading or unloading

● Easy to do maintains job in side the machine.

● Machine working stable during cutting thick material.

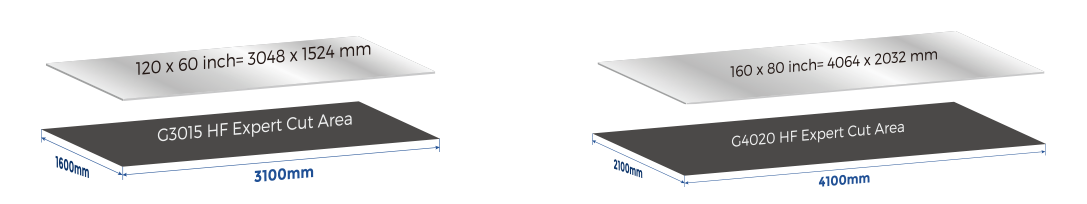

Larger Cutting Area

Increased cutting area,be able to cut AS (American standard) sheet in “inch” size.

Modular Cutting Workbench

Modular universal interchangeable design, with higher, thicker, and denser support cards, better resistance to high-power cutting, and convenient regular maintenance and replacement.

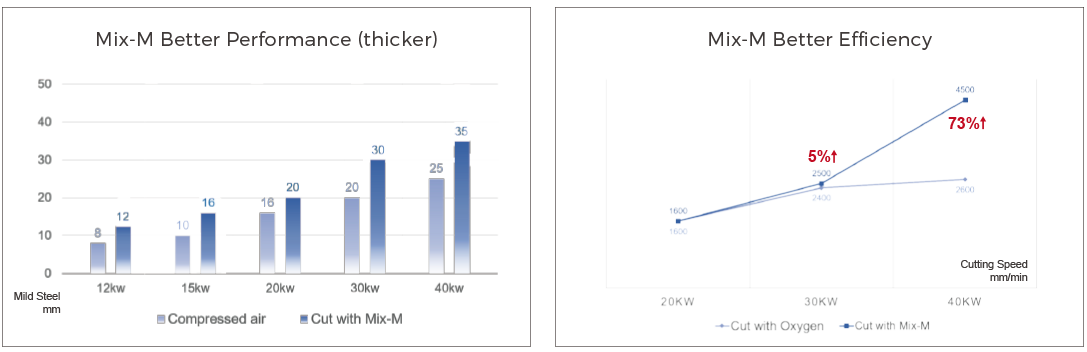

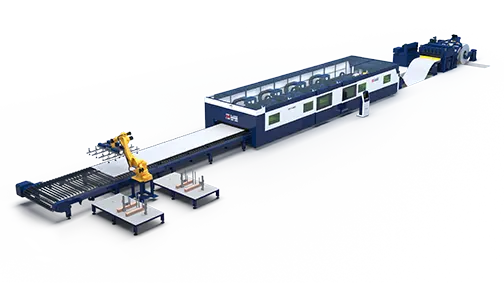

Mix-M Device

Gas mixing cabinet patent of Han's Laser (Optional)

Mix-M process function: equipped with a 20kW or higher power laser, suitable for rapid cutting of 10~40mm carbon steel, solving the problem of traditional medium and thick plate cutting sections and corner slag hanging, effectively improving the upper and lower taper and roughness of the workpiece, greatly improving processing efficiency and workpiece accuracy.

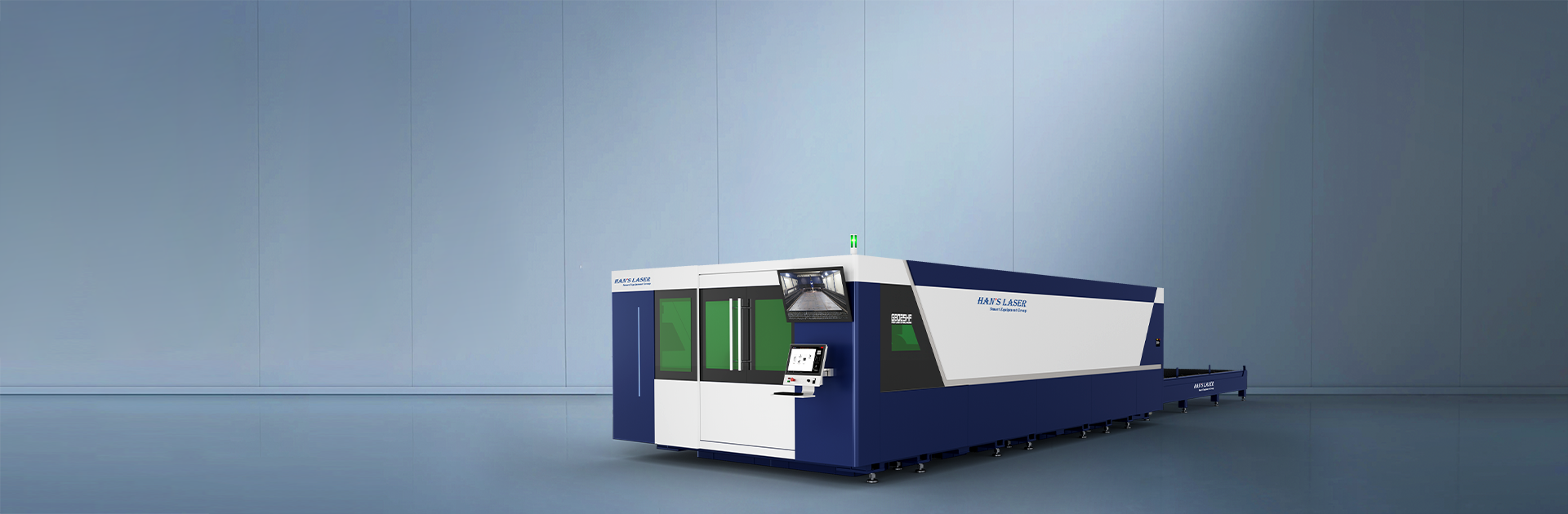

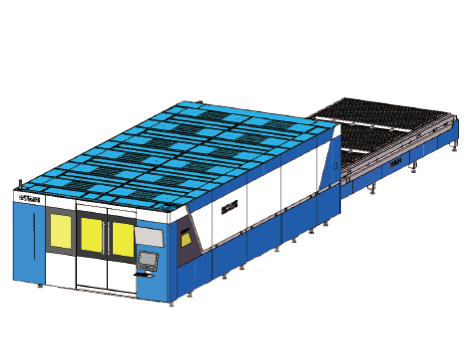

HF Series

Working area

Max. Axis positioning speed (X/Y)

Max. Acceleration

Repeatability

Max. load weight

3150mmx1620mm

200m/min

2.8g

0.02mm

2150kg

4100mmx2100mm

200m/min

2.8g

0.02mm

3840kg

6200mmx2600mm

160m/min

2.5g

0.02mm

7200kg

8200mmx2600mm

160m/min

2.5g

0.02mm

9600kg

10100mmx2600mm

140m/min

1.5g

0.05mm

12000kg

12100mmx2600mm

140m/min

1.5g

0.05mm

14100kg

12100mmx3100mm

140m/min

1.5g

0.05mm

16000kg

contact us

LET’S TALK

LET’S TALK