How Laser Cutting Is Transforming Metallurgical Manufacturing in the Industry 4.0 Era

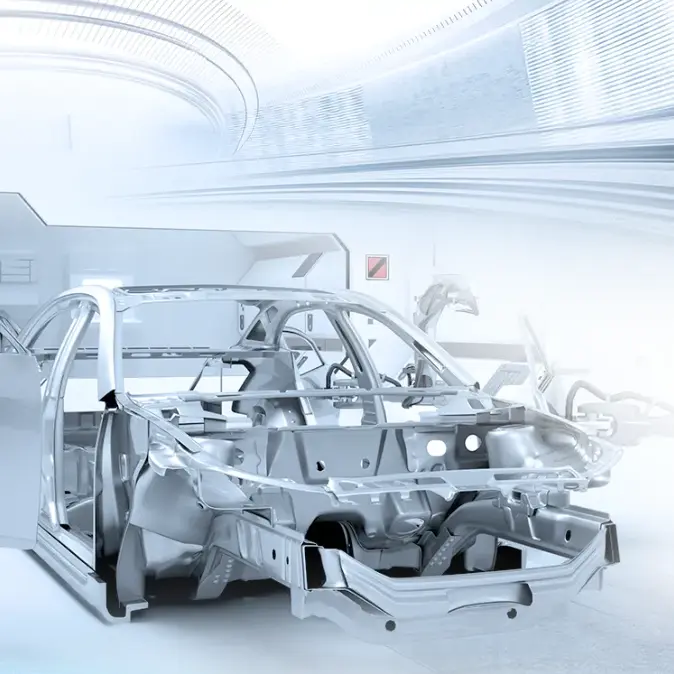

As the global manufacturing landscape embraces Industry 4.0, the metallurgical industry is undergoing a critical transformation. Traditional fabrication methods are giving way to intelligent, automated, and high-precision processes. Among these, laser cutting technology stands out as a game-changer, offering unmatched accuracy, speed, and efficiency. This article explores the core principles, key applications, benefits, and future prospects of laser cutting in metallurgical manufacturing, showcasing its growing importance in modern industry.

What is Laser Cutting Technology?

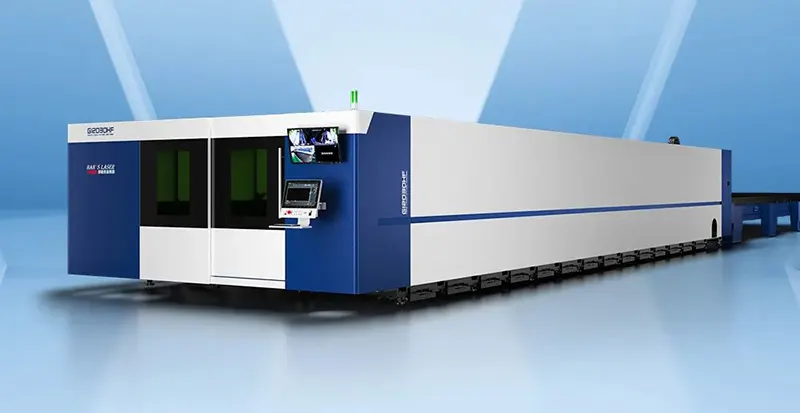

Laser cutting is a non-contact thermal process that uses a focused, high-power laser beam to melt, burn, or vaporize materials along a defined path. Assisted by high-speed gas flow, it delivers clean, precise cuts across various metals. In metallurgical manufacturing, laser cutting enables the production of complex components with tight tolerances and superior edge quality.

Key Applications of Laser Cutting in the Metallurgical Industry

1. Blast Furnace Equipment Fabrication

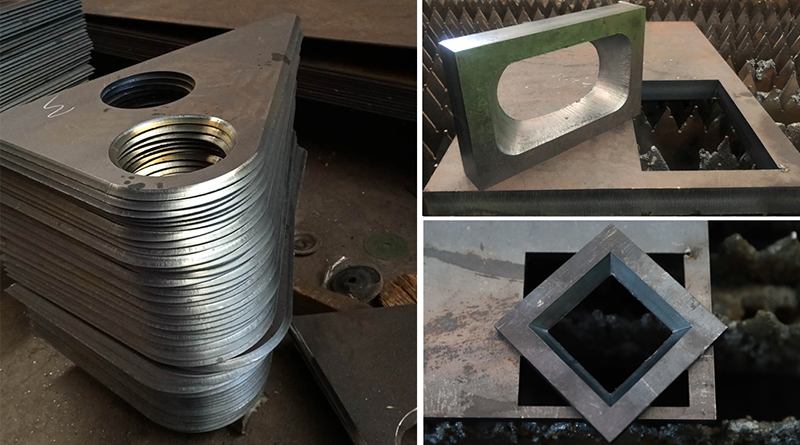

Blast furnaces require robust, large-scale components often made from thick carbon steel or stainless steel. These parts demand high cutting accuracy to ensure structural integrity and operational reliability.

Han's Laser HF Series laser cutters, with advanced focal control and adaptive power modulation, efficiently process materials from 6 mm to 30 mm thick. The result is faster throughput, reduced rework, and improved manufacturing consistency for blast furnace components.

2. Environmental Dust Removal and Purification Systems

As the metallurgical sector faces stricter environmental standards, the demand for dust collection and air purification equipment has surged. These systems rely on accurately cut metal frames and panels for optimal performance.

The Han's Laser BF Series machines excel in bevel cutting, allowing for single-pass, high-precision cuts. This ensures tighter welds, improved structural stability, and better product durability.

3. Pressure Vessel Manufacturing

Pressure vessels, used for storing and transporting gases and liquids under high pressure, require flawless fabrication to meet stringent safety and quality standards. Laser cutting meets these requirements with ease.

Han's Laser HF Series machines feature nano-micro joint technology and frequency-variable perforation. These innovations allow for efficient cutting of thick plates with minimal slag, low taper, and smooth edges—ideal for pressure vessel applications.

Benefits of Laser Cutting in Metallurgical Manufacturing

1. High Precision and Stability

Laser cutting offers unmatched accuracy, ensuring components meet tight specifications with minimal deviation. This results in reduced scrap rates, less post-processing, and higher product quality.

2. Superior Efficiency and Flexibility

Unlike traditional cutting methods, laser cutters can rapidly switch between different material types, thicknesses, and designs. This agility helps reduce production time and increases output, making it ideal for both prototyping and mass production.

3. Energy Efficiency and Environmental Sustainability

Laser cutting is a clean, energy-efficient process that minimizes material waste and environmental impact. Its non-contact nature also extends tool life and reduces maintenance costs. Integrating laser systems supports green manufacturing goals in the metallurgical sector.

Future Outlook: Smart and Sustainable Laser Cutting

1. Automation and Intelligent Integration

Future laser cutting machines will leverage AI and machine learning to self-optimize cutting paths, monitor material conditions, and reduce human intervention. Integration with smart factory systems will enable fully automated production lines, enhancing productivity and consistency.

2. Adaptation to New Materials and Technologies

As advanced materials like high-strength steel and titanium alloys become common, laser systems will evolve to meet new cutting demands. Innovations in laser source technology and process parameters will unlock new possibilities in high-performance metallurgy.

3. Driving Green and Sustainable Manufacturing

As the industry transitions to more sustainable practices, laser cutting will play a vital role in reducing carbon footprints. Enhanced energy-saving capabilities and cleaner operations will make it central to the metallurgical industry’s environmental strategy.

Conclusion

Laser cutting technology is revolutionizing metallurgical equipment manufacturing, offering high precision, efficiency, and flexibility. As Industry 4.0 continues to shape the future of production, laser cutting will become increasingly intelligent, automated, and sustainable. By adopting laser cutting, metallurgical manufacturers not only improve product quality and efficiency but also align with global trends toward green, smart manufacturing. The future of metallurgy is being shaped—one precise laser cut at a time.

Previous

Previous

LET’S TALK

LET’S TALK