Transform Your Steel Fabrication Workflow:Laser Cutting for Structural Steel Processing

In an era where efficiency, precision, and sustainability define industrial success, structural steel remains a cornerstone of construction, shipbuilding, heavy machinery, and infrastructure projects. However, traditional steel processing methods—reliant on multiple machines for drilling, sawing, milling, and plasma cutting—are increasingly incompatible with today's demand for streamlined, eco-conscious manufacturing. Enter Han's Laser's Structural Steel Laser Cutting Machine, a breakthrough solution engineered to transform fabrication workflows.

The Limitations of Traditional Steel Processing

Conventional structural steel fabrication involves disjointed processes:

Multi-machine dependency: Separate tools for drilling, cutting, beveling, and marking.

High costs: Significant capital investment in equipment and labor.

Material waste: Inefficient nesting and manual errors lead to excess scrap.

Time delays: Frequent repositioning and setup between processes.

These challenges erode profitability and hinder compliance with green manufacturing standards.

Han's Laser Cutting Machine: A Unified, Automated Solution

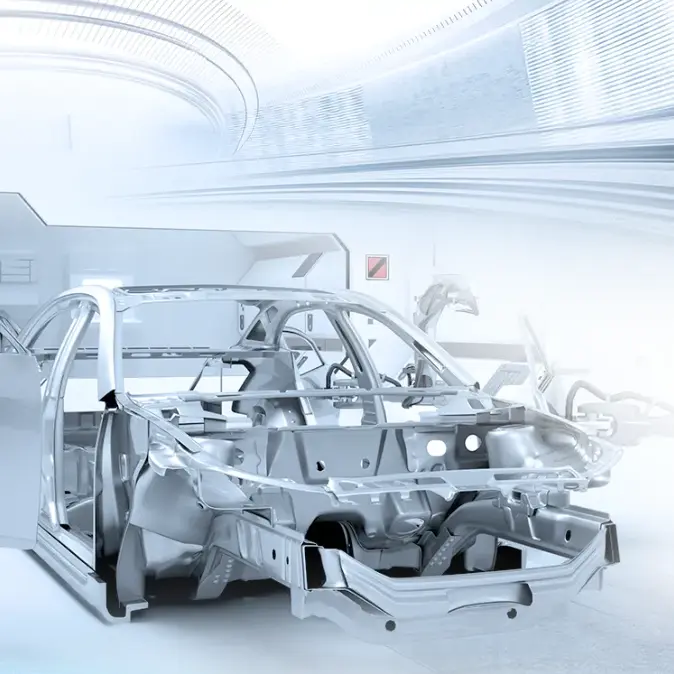

Our advanced structural steel laser cutting system integrates cutting-edge technology to consolidate every critical fabrication step into a single, automated operation. H12560LBF,designed for heavy-duty H-beams, I-beams, and channel steel (up to 1250 × 600 mm), this machine delivers:

1. All-in-One Processing Solution

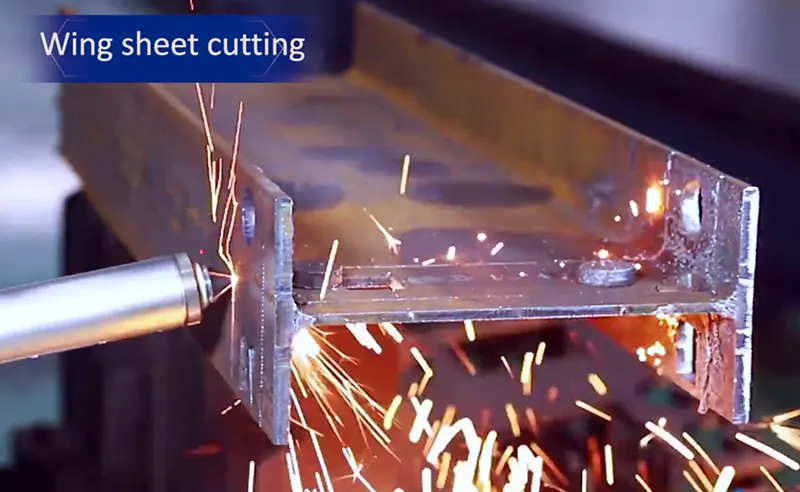

Han’s Laser structural steel cutting system integrates laser cutting, hole drilling, notching, beveling, and marking into a single fully automated operation. It is compatible with Tekla 3D nesting software, ensuring seamless workflow and precise execution directly from digital design to final part.

2. Handles Large Structural Components

Designed for large-format structural steel, this system accommodates profiles up to 1250 × 600 mm, including H-beams, I-beams, and channel steel. An automated loading and unloading system streamlines the entire process, reducing manual intervention and increasing safety.

Key Advantages

✅ High-Speed Precision Cutting

Laser technology delivers clean, burr-free edges with high accuracy, reducing the need for secondary processing and improving overall part quality. Compared to plasma or mechanical cutting, laser cutting ensures a more refined finish.

✅ Boosted Production Efficiency

By consolidating multiple fabrication steps into one, the machine significantly reduces setup time, material handling, and cycle duration, maximizing production throughput.

✅ Minimized Material Waste

Advanced nesting software maximizes sheet utilization, reducing offcuts and lowering material costs—a key aspect in sustainable manufacturing practices.

✅ Better Fit-Up for Welding and Assembly

Precision cutting ensures perfect fit-ups, reducing rework and improving welding accuracy. This shortens the assembly cycle and increases the strength of the final product.

✅ Cost Savings and Competitive Advantage

Eliminating multiple machines and labor-intensive processes results in lower operating costs, fewer errors, and higher consistency, giving manufacturers a clear edge in today's competitive market.

Industries Transformed by Laser Cutting Technology

Han's Laser systems are reshaping fabrication across sectors:

Construction & Infrastructure: Rapidly produce beams, columns, and trusses for stadiums, high-rises, and industrial plants.

Shipbuilding & Offshore: Precision-cut steel plates and profiles for hulls, decks, and offshore platforms.

Rail & Transportation: Fabricate railway tracks, station components, and cargo systems with flawless fitment.

Heavy Machinery: Process thick steel parts for mining, agricultural, and construction equipment.

Why Choose Han's Laser for Structural Steel Fabrication?

Future-Ready Technology: Our machines adapt to Industry 4.0 standards, offering IoT connectivity for real-time monitoring and predictive maintenance.

Enhanced Welding Readiness: High-precision cuts ensure perfect alignment, reducing welding time and improving joint integrity.

Global Support Network: 24/7 technical assistance and spare parts availability worldwide.

Drive Competitiveness with Laser Cutting Innovation

As structural steel projects grow in complexity and scale, manufacturers must adopt agile, eco-friendly technologies to stay ahead. Han's Laser's structural steel laser cutting machine empowers businesses to:

Accelerate project timelines.

Achieve a more sustainable production line

Reduce total cost of ownership.

Deliver superior-quality components.

Upgrade Your Fabrication Workflow Today

Don't let outdated methods constrain your growth. Discover how Han's Laser's automated, high-speed cutting solutions can elevate your structural steel production.

Upgrade your fabrication process today—choose Han's Laser for the future of structural steel processing.

Previous

Previous

LET’S TALK

LET’S TALK