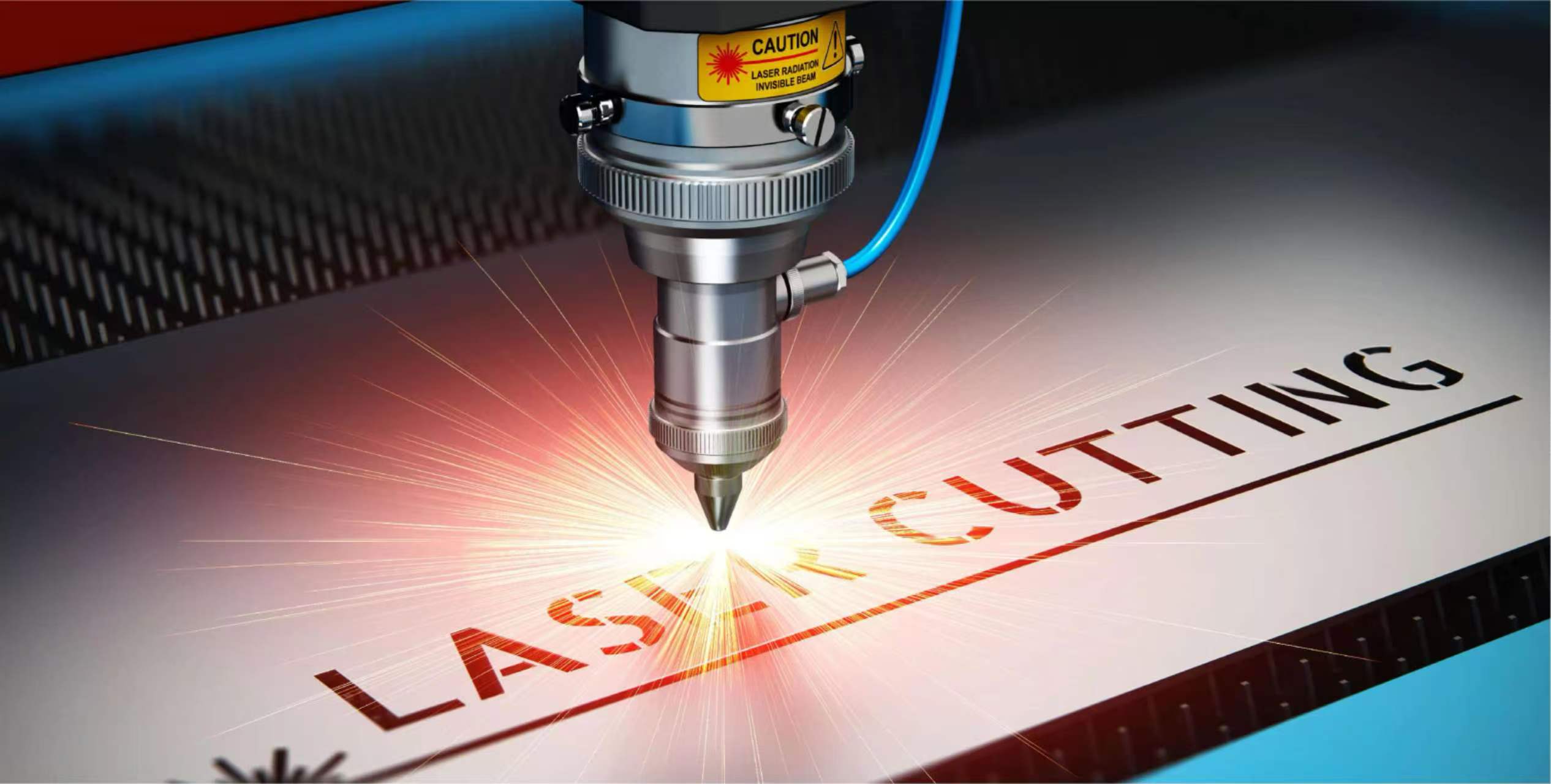

Unlocking Efficiency with Fly Cutting in Fiber Laser Machines

Maximize speed, precision, and profits with this advanced laser cutting technique

Fiber laser cutting has transformed modern manufacturing with its precision and speed. But did you know there’s a method that can make it even faster and more cost-effective? It’s called fly cutting, also known as “on-the-fly” mode. When paired with the right software, fly cutting can dramatically boost productivity while reducing wear, waste, and energy use.

In this article, we’ll explain what fly cutting is, how it works, its key benefits, and when to use it for optimal results.

What Is Fly Cutting?

Fly cutting is a high-speed laser cutting technique that enables the laser head to move continuously in horizontal and vertical grid patterns, switching the beam on and off precisely at the cutting points—without stopping for each individual shape.

This method is ideal for processing large volumes of identical holes or geometric patterns, such as ventilation grids or perforated sheets. Instead of stopping and restarting at each cut, the machine executes multiple cuts in one continuous movement.

📈 By optimizing the laser path and reducing idle movement, fly cutting can cut production time by up to 50%.

How Does Fly Cutting Work?

Traditional laser cutting follows the outline of each shape, one at a time. In contrast, fly cutting moves the laser head in a sweeping motion—like drawing with a ruler across a grid—and activates the beam only at the edges.

Key principles:

Grid-based movement: Laser travels in straight lines, turning the beam on and off at cutting zones.

Tangential turns: Instead of sharp corners, the laser head makes smooth directional changes, reducing mechanical stress.

Minimal up-and-down movement: The head stays level with the material, speeding up the process.

This approach minimizes laser activation time, reduces wear on machine parts, and maximizes the use of cutting energy.

Types of Laser Cutting Techniques

Aside from fly cutting, several laser cutting strategies are available depending on the material and shape complexity:

Normal Cutting: Traditional one-shape-at-a-time method; best for complex or thick materials.

Common Line Cutting (CLC): The machine identifies shared edges between parts to reduce redundant cuts.

Common Pierce Point: Multiple shapes start from a single pierced point to save time and energy.

Fly Cutting (Grid Cutting): Focuses on speed and efficiency by cutting many simple shapes simultaneously.

Advantages of Fly Cutting

Faster Production

Cuts multiple shapes at once, reducing total cycle time.

Especially efficient for perforated or repeated-pattern sheets.

Improved Energy Efficiency

Less beam activation and fewer pierce points reduce power consumption.

Smooth directional changes preserve mechanical components.

Reduced Material Waste

Less "slug" (excess material) is produced.

Optimized paths result in cleaner edges and reduced kerf width.

Extended Machine Life

Lower mechanical stress means fewer maintenance needs.

Precision movement leads to reduced wear on motors and gears.

Higher Profit Margins

Time and material savings directly improve operational costs.

Even a 4% process improvement can save tens of thousands annually in high-volume operations.

When Not to Use Fly Cutting

Although powerful, fly cutting isn't ideal for every situation.

Material Limitations

Best for thin materials (1mm or less).

Less effective on reflective materials like aluminum or stainless steel due to poor laser absorption.

Complex Geometries

Grid-based cutting isn’t suitable for curves or irregular shapes.

Better used for simple, repetitive patterns (e.g., square or round holes).

Risk of Collision

Improper path planning or low assist gas pressure can lead to slugs bouncing back and damaging the head.

Use reliable CAM software to mitigate these risks.

Software That Supports Fly Cutting

Fly cutting requires intelligent path optimization. Here are some top-performing software options:

CypCut: All-in-one CAD/CAM software for fiber laser CNC machines; great for error correction and path control.

JetCAM: Known for its powerful nesting algorithms and ease of use in industrial settings.

Cut Assist : Interactive interface that fine-tunes speed, frequency, and laser width for fly cutting.

Final Thoughts: Is Fly Cutting Right for You?

Fly cutting is an advanced technique that unlocks new levels of speed, efficiency, and profitability in fiber laser cutting. While it's not ideal for every material or design, it's a game-changer for high-volume production with repeated patterns.

By choosing the right equipment and software, manufacturers can significantly reduce lead times, lower operational costs, and extend machine lifespan—all while maintaining precision and quality.

Previous

Previous

LET’S TALK

LET’S TALK