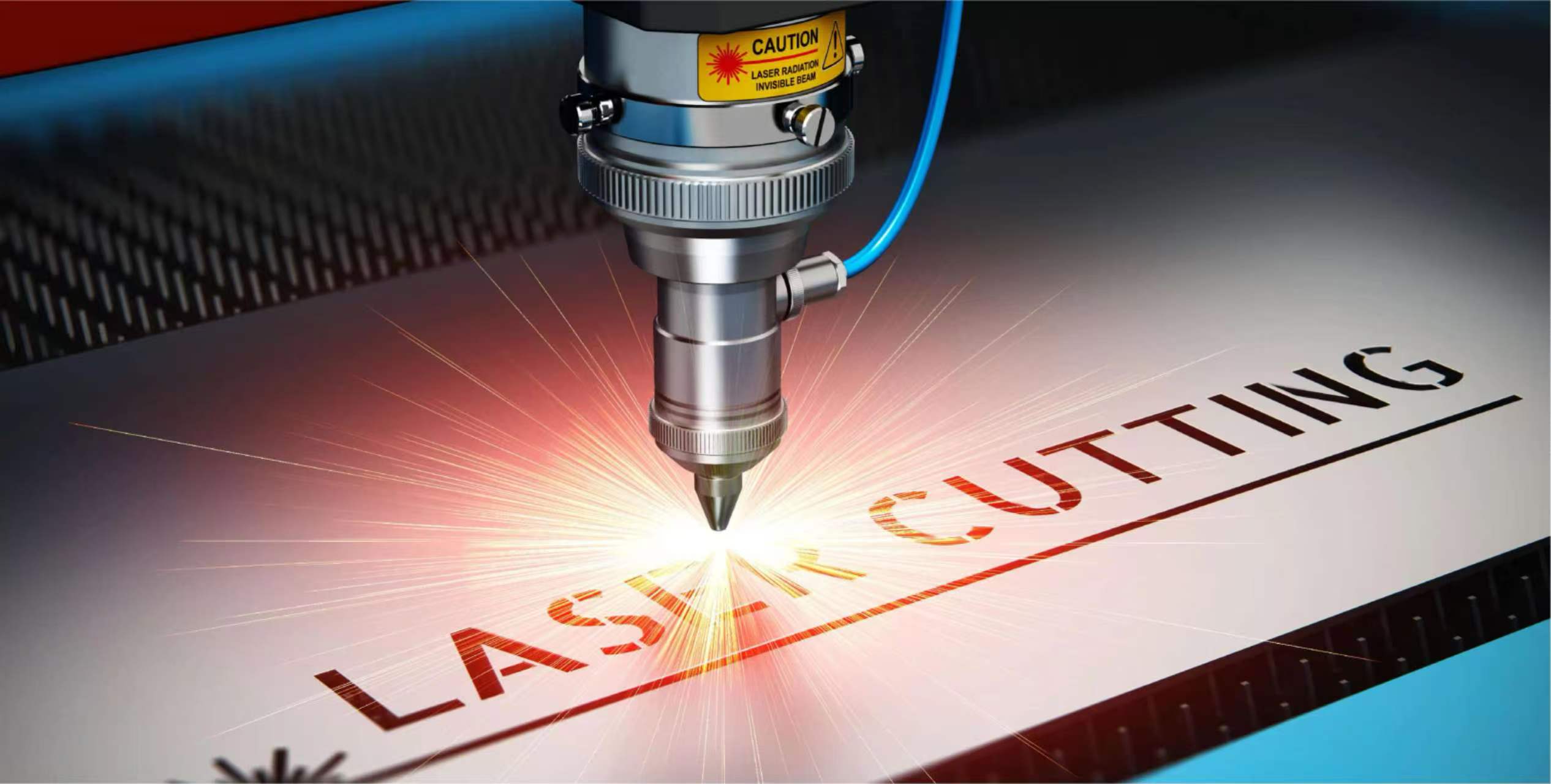

As the world shifts toward a sustainable energy future, advanced manufacturing technologies are essential in supporting this transformation. Among these technologies, laser cutting has become a vital enabler of industrial upgrades within the new energy sector. Known for its flexibility, precision, and efficiency, laser cutting aligns perfectly with the industry's focus on intelligent, green production methods.

As a global leader in laser intelligent equipment, Han's Laser offers cutting-edge integrated laser solutions that empower industries to adopt innovative, smart manufacturing processes. In the new energy sector, Han's Laser provides comprehensive solutions for electric vehicle (EV) manufacturing, energy storage systems, photovoltaic components, and battery production, driving the transition toward high-efficiency, low-carbon operations.

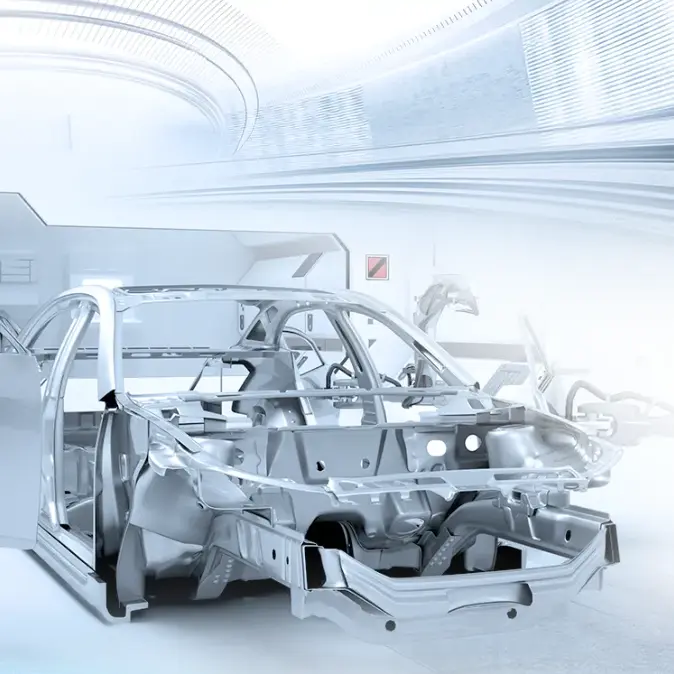

Advanced Lightweight Manufacturing for New Energy Vehicles (NEVs)

Lightweight design is a key trend in the electric vehicle (EV) industry. To support this, Han's Laser has developed a range of advanced 3D five-axis laser cutting machines that cater to every stage of production—from small-batch prototyping to large-scale manufacturing.

Modern EVs commonly incorporate lightweight materials like aluminum alloys, carbon fiber, and high-strength steel. While these materials offer excellent strength-to-weight ratios, they present challenges when processed with traditional stamping or punching methods. Han's 3D five-axis laser cutting machine, featuring an innovative self-developed cutting head with auto-focus, three-point positioning, and fast piercing, delivers precise trimming and hole cutting for complex 3D hot-stamped parts in a single operation.

Applications for Critical Automotive Components

This advanced laser cutting technology is perfect for essential automotive parts, including A-pillars, B-pillars, door rings, and battery trays. By reducing the need for molds, this technology lowers tooling costs and shortens prototype development cycles, providing car manufacturers with greater flexibility and cost-effectiveness.

Han's laser cutting machines are built on a signature gantry structure, optimized through CAE analysis and extensive performance testing to ensure exceptional rigidity and stability. The upgraded drive system achieves an idle running speed of 120 m/min with acceleration up to 1.2 g, enhancing response time and cutting accuracy. Dynamic parameter adjustments ensure burr-free cuts, improving both part quality and reliability—making laser cutting an indispensable tool for mass production in the NEV industry.

Integrated Sheet Metal Solutions for Energy Storage Systems

Energy storage is another critical component of the new energy landscape. A complete storage system typically consists of control units, batteries, inverters, and sheet metal enclosures. The quality and cost of these enclosures are crucial for system performance and market competitiveness.

Han's Laser provides a comprehensive suite of sheet metal processing solutions, integrating flatbed laser cutting, tube cutting, bending, and automated production lines to streamline the manufacturing process.

Precision Sheet Metal Cutting for Energy Storage

Han's flatbed laser cutting machines offer high precision and clean, smooth edges, eliminating the need for secondary processing before bending. When paired with automated bending units, these machines reduce material handling and significantly increase throughput.

For structural components like frames, legs, and support columns, Han's laser tube cutting machines can process a variety of profiles—square, round, oval, and custom shapes—including angle and H-beams, in one efficient step. This one-stop solution covers cutting, hole processing, and beveling, ensuring structural integrity while improving production efficiency.

After laser cutting and bending, components undergo coating, welding, assembly, and inspection, creating an integrated production flow. This seamless process not only increases productivity but also reduces costs, supporting the rapid scaling of energy storage systems.

Laser Cutting: Enabling a Sustainable Energy Future

The rise of the new energy sector is driving green transformation in industries like transportation, manufacturing, and construction across the globe. Laser cutting technology is at the forefront of this transformation, providing solutions for greater precision, cleaner processes, and more efficient production methods.

Han's Laser is committed to continuous innovation and customer-focused solutions, offering the advanced tools necessary to build a sustainable and intelligent energy future.

Previous

Previous

LET’S TALK

LET’S TALK