Integrated Steel Profile Processing Solutions for Modern Construction and Heavy Industry

Steel profiles such as H-beams, I-beams, channels, angles and flat bars form the structural backbone of modern industrial facilities—high-rise buildings, long-span bridges, communication towers and complex steel frameworks. Their advantages in strength, speed, lightweight design and sustainability make them indispensable in today’s engineering landscape.

Yet, the processing of steel profiles remains challenging. Traditional methods often struggle with accuracy, efficiency and flexibility, slowing down overall productivity.

Han’s Laser addresses these shortcomings with a complete, laser-driven processing chain, covering cutting, heavy-duty bending and advanced welding technologies to support continuous industrial upgrading.

The Complexities of Steel Profile Processing

Steel profiles come in a wide range of shapes and dimensions. Conventional processing is restricted by both material characteristics and outdated techniques:

-

1.Irregular placement and deformation during welding often result in offset cuts and dimensional inaccuracies.

-

2.Tapered, unequal-thickness or variable-height sections pose significant challenges for positioning and cutting.

-

3.Operations such as beveling, end-cutting and weld-seam cleanup require sophisticated handling that traditional tools cannot reliably achieve.

These issues collectively hinder manufacturers from reaching the output quality and efficiency demanded by modern construction projects.

Han's Laser Full-Process Steel Profile Processing Solution

To overcome these challenges, Han's Laser offers a mature and scalable workflow that integrates laser cutting, bending and intelligent welding—creating a highly efficient, precision-focused production environment.

1. Laser Cutting – The Basis of Accuracy and Efficiency

1)H-Beam and Structural Profile Laser Cutting Machine

Industries such as construction, bridge building and offshore engineering traditionally rely on manual marking, flame cutting and multi-step drilling to process structural profiles. These segmented processes reduce accuracy and slow down production.

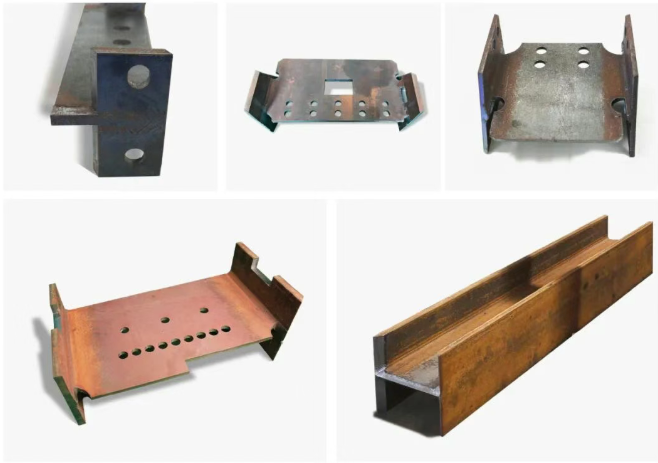

Han's Laser H-series machines consolidate multiple processes into a single, automated system and support:

-

1.Cutting of H-beams, I-beams, channels, angles and flat bars

-

2.Optional integration of flat-sheet processing

-

3.Drilling, beveling, slotting, marking and cutting in one setup

Key System Advantages

-

1.HAN'S 901-3D CNC platform with a specialized process database

-

2.Direct compatibility with Tekla Structures, enabling one-click code generation

→ Eliminates the entire Tekla–CAD–CAM conversion workflow -

3.Intelligent nesting software for optimized material usage

-

4.Custom-engineered 3D profile cutting head for clean roots and high-precision edge quality

All critical features can be completed in a single pass, eliminating repeated clamping and significantly improving overall accuracy.

2)WTX Heavy-Duty Four-Chuck Laser Tube & Profile Cutting Machine

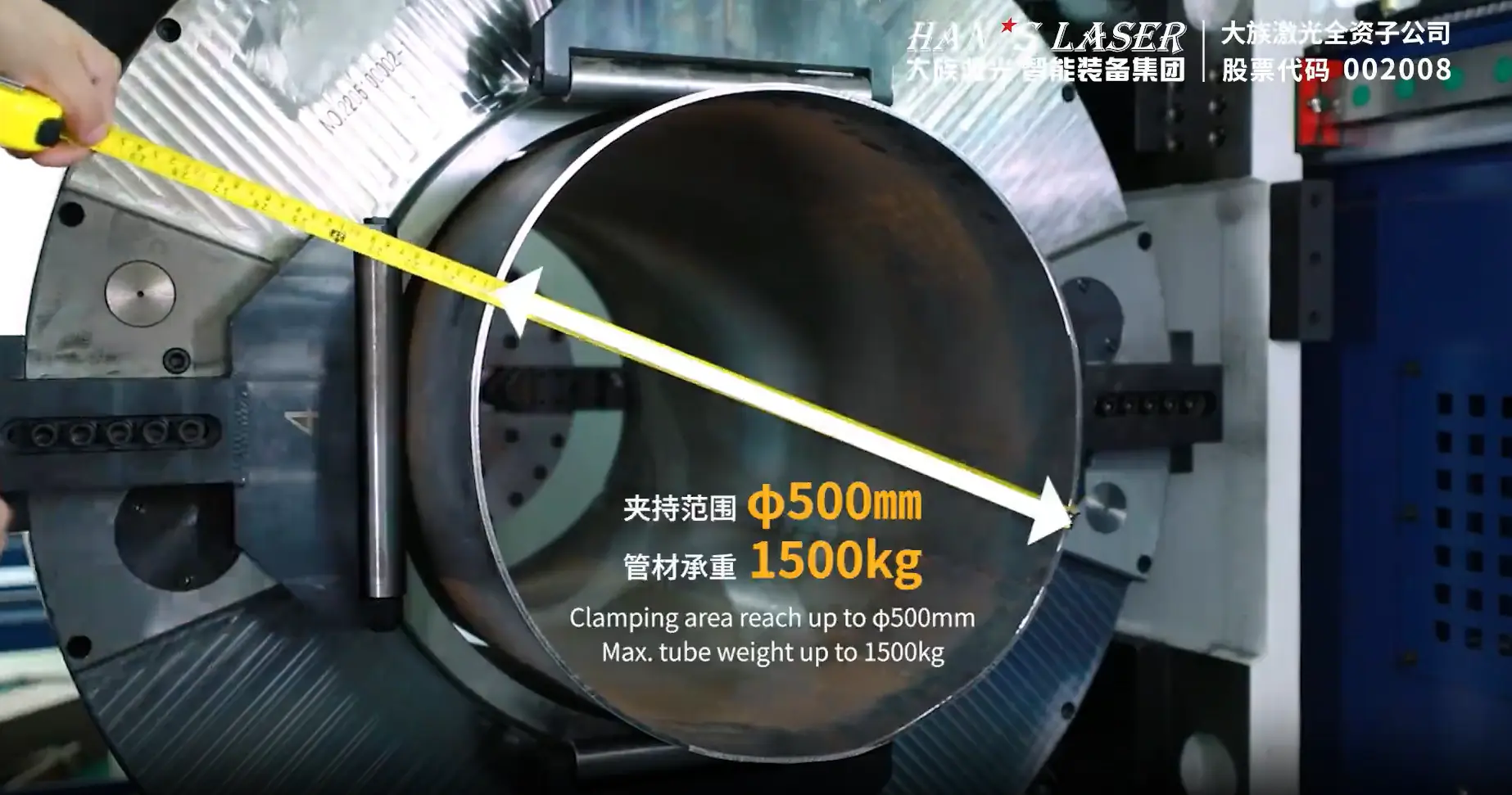

For extra-long and heavy profiles used in transmission towers, telecom towers and other large steel structures, the WTX series provides a specialized high-capacity solution.

Features include:

-

1. Four-chuck high-precision structure ensuring stable clamping and no-blind-zone cutting

-

2. Simultaneous loading and unloading for continuous production

-

3. Dual-chuck discharge system allowing rotated stacking—ideal for angles and channels

-

4. Bevel cutting head supporting 0–45° bevels and straight cuts in one operation

The machine is engineered for large tower-steel applications where accuracy and throughput are equally critical.

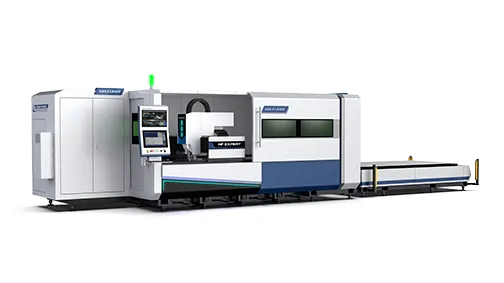

3)Large-Format High-Power Laser Cutting Machine

For plates such as connection plates and node plates in steel structures, Han's Laser offers high-power, large-format cutting systems that provide:

-

1.Smooth surfaces with minimal dross

-

2. Precise cutting & drilling completed in a single pass

-

3.No need for secondary finishing

-

4.Much smaller heat-affected zone compared to plasma or oxy-fuel

-

5.Improved structural reliability for critical components

This results in consistent quality and greater long-term stability for engineering projects.

2. Heavy-Duty Bending – Reinforcing Structural Strength

Steel structure components often rely on thick plates for load-bearing and connection functions. Traditional welding processes increase workload, energy consumption and the risk of deformation. Bending, however, enhances strength without compromising material integrity.

Han's Heavy-Duty Press Brake Advantages

-

1.High-rigidity frame optimized via FEA analysis

-

2.Large open height & extended stroke to handle oversized plates

-

3.Integrated hydraulic system with corrosion-resistant stainless-steel tank

-

4.Lower energy consumption and reduced risk of valve failures

-

5.Bidirectional mechanical crowning table

→ Compensates for deformation during bending

→ Ensures consistent angles and straightness over long lengths

Models range from 500 to 1200 tons, supporting up to 30 mm plate thickness—ideal for large construction components.

3. Advanced Welding – Redefining Steel Structure Manufacturing

1)Laser-Arc Hybrid Welding

Laser-arc hybrid welding combines the deep penetration of laser welding with the strong bridging capability of arc welding. For thick-plate structures, this method provides:

-

1.No need for traditional bevel preparation

-

2.Narrower weld seams and reduced excess

-

3.Deeper penetration and lower heat input

-

4.Reliable single-sided welding, double-sided forming

Han's hybrid welding systems are widely used in:

-

1.T-beam & channel steel fabrication

-

2.Stainless steel and aluminum components in rail transit

-

3.Large shipbuilding structures such as decks and bulkheads

The technology supports both high-strength materials and complex curved surfaces.

2)Teaching-Free Intelligent Arc-Welding Robot

Han's Laser intelligent welding robot integrates a smart welding controller with a 3D laser seam-tracking scanner, enabling:

-

1.Automatic recognition of weld-seam position and geometry

-

2.Real-time path planning and torch-angle optimization

-

3.One-click generation of welding trajectories

The system supports multi-pass welding, fillet welding and continuous long-seam processing. With a 2-meter arm reach and ±0.08 mm repeatability, it is ideal for:

-

1.H-beam (including butt welds)

-

2.Brackets and gusset plates

-

3.Bridge plates and lattice structures

-

4.Tower-foot assemblies

It is particularly effective in small-batch, multi-variety production scenarios common in steel-structure and bridge construction.

A Complete Workflow for Intelligent Steel Profile Manufacturing

By integrating cutting, bending and welding technologies into a single ecosystem, Han's Laser delivers a comprehensive and reliable solution for every stage of steel profile processing. With advanced equipment, deeply integrated software and continuously optimized processes, manufacturers can:

-

1.Break through traditional productivity limits

-

2.Improve consistency and reduce rework

-

3.Reduce operating costs

-

4.Shorten delivery cycles

-

5.Achieve stable, high-quality production output

Han's Laser will continue expanding its “Laser+” and “Intelligent+” technologies, empowering global manufacturers to accelerate their digital transformation and build a more efficient, high-quality production future.

LET’S TALK

LET’S TALK