What Materials Can a 20kW Laser Cutting Machine Process?

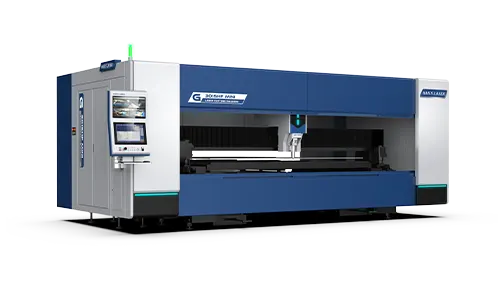

In modern heavy-duty manufacturing, cutting speed and material adaptability are critical. A 20,000W fiber laser cutting machine represents the pinnacle of industrial laser technology, delivering unmatched performance in handling thick, dense, and reflective metals. But what exactly can a 20kW laser cutter handle—and in which industries does it offer the most value?

Let's explore the cutting capabilities, application scenarios, and key advantages of this ultra-high-power laser solution.

Superior Cutting Performance for Thick and Reflective Metals

The core strength of a 20kW fiber laser lies in its ability to cut through thick sections with high precision and speed, even when dealing with materials traditionally considered difficult to process.

✓ Carbon Steel

-

Clean, high-speed cuts up to 22mm with air assist

-

With oxygen assist, even thicker sections are manageable

✓ Stainless Steel

-

Smooth, burr-free edges on materials 20mm and thicker

-

Ideal for parts requiring minimal post-processing

✓ Aluminum & Aluminum Alloys

-

Cuts up to 18mm or more, depending on alloy composition and assist gas

-

Overcomes aluminum's reflectivity and thermal conductivity challenges

✓ Copper & Brass

-

Traditionally challenging for lasers, but easily processed with 20kW power

-

Excellent cut quality due to stable beam delivery and peak energy density

With this power level, it's also possible to cut 10mm carbon steel at speeds exceeding 11 m/min, making it highly productive for mass production environments.

Tailored for High-Demand Industrial Applications

A 20,000W laser cutter is engineered for operations where precision meets scale. It is an essential tool in industries that depend on cutting thick sheet metal and structural components efficiently.

1. Shipbuilding & Marine Engineering

-

Cuts large steel plates with reduced heat deformation

-

Speeds up panel fabrication and weld seam preparation

2. Bridge & Infrastructure Projects

-

Produces structural elements with clean edges and precise dimensions

-

Improves consistency in critical load-bearing components

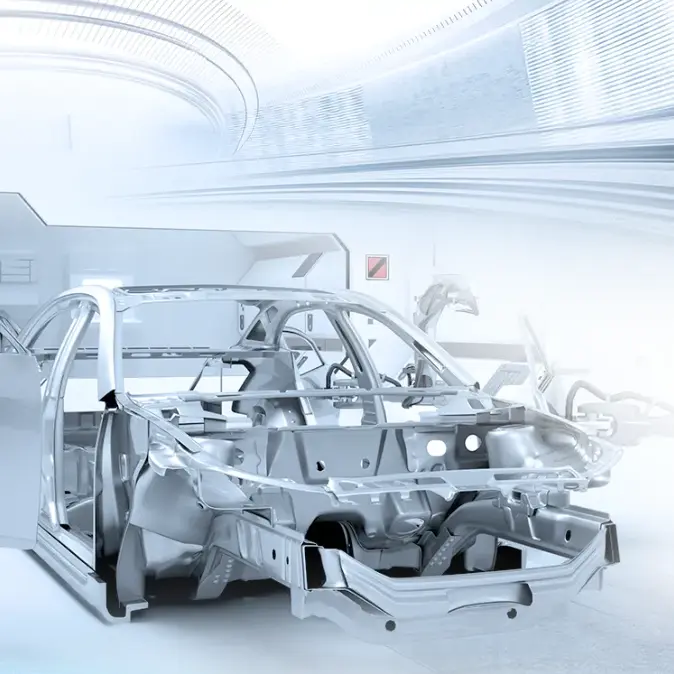

3. Heavy Equipment Manufacturing

-

Ideal for cutting equipment frames, thick plates, and reinforcement parts

-

Reduces processing time without sacrificing quality

4. Steel Service & Processing Centers

-

Expands service range to include thicker and more diverse metals

-

Increases throughput and accelerates custom order delivery

Beyond Power: Intelligent Features That Boost Efficiency

Today's 20kW systems aren't just brute force—they're smart. High-end models are packed with advanced automation and monitoring features that support 24/7 production:

-

Auto Nozzle Changers – Enable seamless switching between materials or thicknesses

-

Real-Time Monitoring – Detect anomalies to ensure consistent performance

-

Adaptive Optics – Maintain optimal beam focus during high-speed operation

-

Smart Nesting Software – Maximize material usage and reduce scrap

These features enhance operational efficiency, reduce manual intervention, and keep your production line running at full speed.

Conclusion: Is 20,000W Right for You?

The 20,000W fiber laser cutting machine is more than just a powerhouse. It's a high-precision, high-speed, and high-efficiency solution designed for the most demanding production needs. From carbon steel to copper, and from batch processing to large-format plates, this system offers the cutting capacity and flexibility to stay competitive in advanced manufacturing.

Explore Han's Laser 20kW Solutions

Thinking of upgrading your production line? Han's Laser offers customized high-power cutting machines, tailored to meet your material demands and industry-specific requirements. Whether you're working with thick steel plates or reflective metals, we're here to help you maximize performance.

FAQ: Common Questions About 20,000W Laser Cutting Machines

Q1: What is the maximum cutting thickness for a 20kW laser machine?

A: The 20,000W fiber laser cutter can process carbon steel up to 30mm, stainless steel around 50mm, aluminum and copper typically up to 18–20mm, depending on material composition and assist gas type.

Q2: Can a 20kW laser cut reflective metals like copper and brass?

A: Yes. Thanks to its high peak power and advanced anti-reflection optics, a 20kW laser can safely and efficiently cut copper, brass, and other nonferrous reflective materials, which are often difficult for lower-power systems.

Q3: Is a 20,000W laser suitable for high-precision parts?

A: Absolutely. Despite its high power, modern 20kW systems are equipped with fine control over beam quality, focus, and motion, making them suitable for both precision parts and large-format structural components.

Q4: What gases are used with a 20kW laser cutter?

A: Common gases include oxygen (for carbon steel), nitrogen (for stainless steel and aluminum), and air (for cost-efficient cuts). The choice depends on the material and the desired edge quality.

Q5: Do I need special training to operate a 20kW system?

A: Yes, due to the system's complexity and power level, professional training is recommended. Han's Laser provides technical support, operator training, and safety guidance for all high-power laser systems.

Previous

Previous

LET’S TALK

LET’S TALK