In today’s fast-paced manufacturing environment, fabricators are under pressure to achieve faster, more cost-effective production without compromising on quality. High-power laser technology is setting new standards in metal fabrication. While many laser manufacturers focus solely on boosting output power, Han’s Laser takes a more comprehensive approach—developing high-performance fiber lasers that provide not only exceptional power, but also superior efficiency, control, and consistency across the entire cutting process.

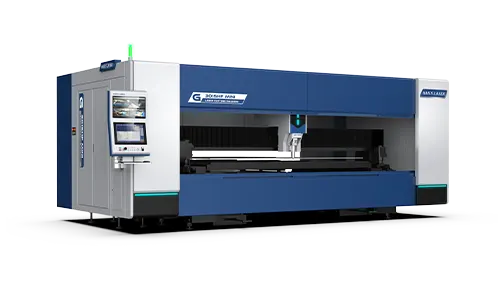

A Complete 20kW Laser Cutting Solution

The Han’s Laser 20kW fiber laser is engineered for high demanding industrial applications. Unlike traditional high-power systems, it strikes the perfect balance between output power, beam stability, and anti-reflection performance. Thanks to fully vertically integrated manufacturing—from pump source to combiner—Han’s Laser ensures strict quality control and unmatched reliability.

When integrated into a laser cutting machine, the 20kW system goes beyond raw power. It enables consistent cutting results, smart process control, and significant gains in productivity.

Whether processing carbon steel, stainless steel, or aluminum, the system guarantees stable performance and high cutting quality, especially for plates up to 50mm thick.

Key Cutting Advantages

Equipped with standard 100/200 cutting heads, the Han’s Laser 20kW solution will deliver remarkable performance:

1. 50mm Carbon Steel (Oxygen Cutting)

•High-speed, clean-edge cutting with minimal dross.

•Up to 35% faster compared to conventional 20kW systems.

2. 20mm Carbon Steel (Air or Nitrogen)

• Stable mass production with reduced operating costs.

• Cutting speed improvement of 30%, ideal for cost-sensitive projects.

3. ≤20mm Carbon Steel (Air Cutting)

• Eliminates nitrogen consumption.

• Maintains cut quality while significantly improving profitability in high-volume production.

4. Stainless Steel & Aluminum Alloys

• Nitrogen or air-assisted cutting with 20–80% faster speeds (depending on thickness).

• Delivers edge quality equal to or better than typical 20kW systems.

Positive focus cutting performance on 16–50mm carbon steel

Negative defocus cutting performance on 16–50mm carbon steel

Nitrogen cutting performance on 16–40mm stainless steel

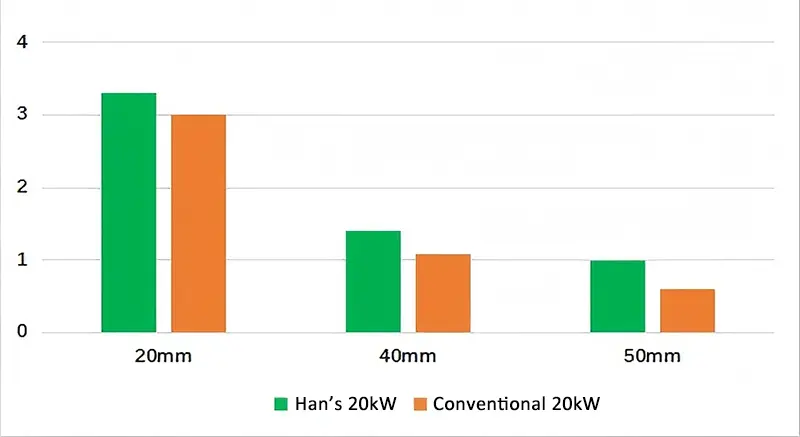

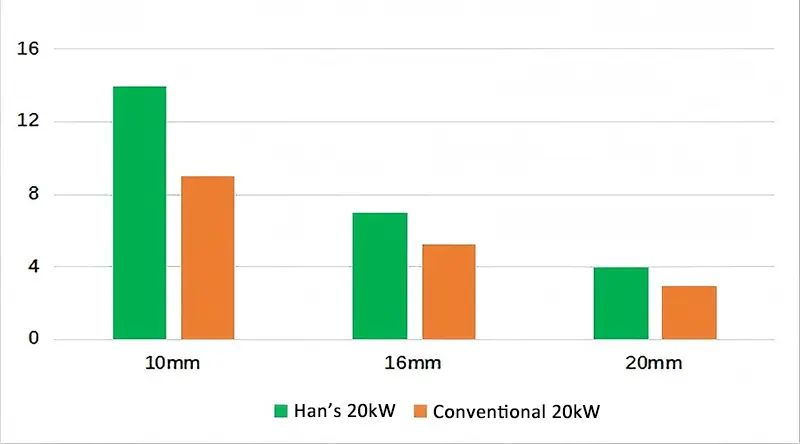

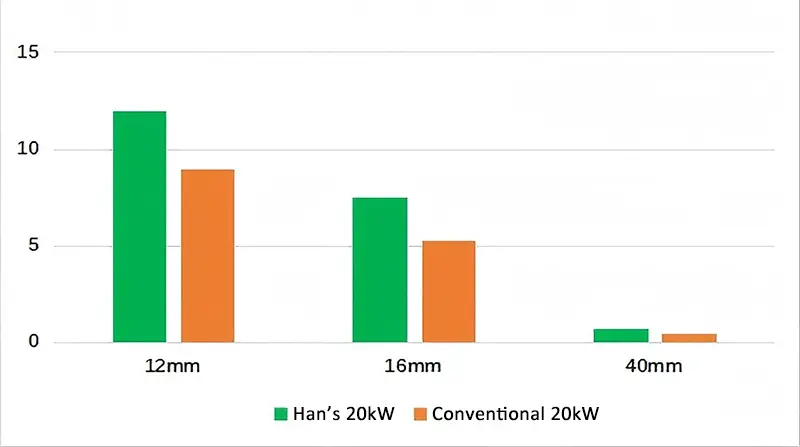

Carbon Steel Oxygen Defocus Cutting Speed Comparison

Carbon Steel Air Cutting Speed Comparison

Stainless Steel Nitrogen Cutting Speed Comparison

Engineered for Modern Manufacturing

The 20kW laser cutting solution helps manufacturers meet today’s market challenges:

• Higher productivity: Faster cutting reduces lead times.

• Lower cost per part: Optimized gas usage and reduced material waste.

• Consistent quality: Precision control ensures repeatable results.

• Sustainability: Clean cutting with reduced emissions compared to traditional methods.

M2.0 Cutting Head Highlights

• 50mm carbon steel (oxygen): +35% cutting speed

• 20mm carbon steel (air): +30% cutting speed

• 40mm stainless steel: +20% cutting speed

• Aluminum alloys: up to +80% cutting speed

Application Fields

The Han’s Laser 20kW fiber laser cutting machine meets the growing demand for high-speed, high-precision, and cost-effective metal fabrication. With the ability to process both thin sheets and thick plates up to 50mm, it delivers reliable results across key industries:

Shipbuilding & Offshore Engineering

Cuts carbon steel up to 50mm with clean edges and minimal dross, ideal for hull sections, reinforcements, and deck plates. Precision reduces rework and boosts structural reliability.

Construction & Structural Steel

Ensures high throughput and consistent accuracy in frameworks, bridges, towers, and custom plates, supporting large-scale infrastructure projects.

Heavy Equipment & Agricultural Machinery

Processes thick brackets, frames, and enclosures quickly and precisely, reducing lead times, waste, and overall fabrication costs.

Automotive & Transportation

Delivers speed and precision for chassis, exhaust, and reinforcement parts. Clean edges eliminate secondary processing and accelerate assembly lines.

Energy & Power Equipment

Handles thick stainless steel and aluminum for wind, solar, and power grid components, ensuring stability and long-term durability.

Metal Fabrication & Job Shops

Flexible gas-switching (oxygen, air, nitrogen) supports diverse materials and thicknesses, helping job shops scale efficiently and remain profitable.

Driving Industrial Competitiveness

With its power, speed, and versatility, the Han’s Laser 20kW system enables:

*Cleaner, more precise cuts

*Faster production cycles

*Lower operating costs

It provides manufacturers with the tools to stay competitive in today’s high-demand metalworking market.

Conclusion

Laser cutting is transforming the steel processing industry—reducing material waste, improving precision, lowering costs, and minimizing environmental impact. With advanced solutions for sheet, coil, tube, and profile cutting, Han’s Laser empowers manufacturers across shipbuilding, infrastructure, machinery, HVAC, fitness, and signage to achieve higher productivity and sustainable growth.

Ready to upgrade your steel fabrication process?

Contact Han’s Laser today to learn how our customized cutting solutions can help you achieve more efficiency, precision, and profitability.

Previous

Previous

LET’S TALK

LET’S TALK