As global manufacturing pivots toward high-end, eco-friendly, and intelligent solutions, Han's Laser answers the call with a new shipment of advanced press brakes tailored for international markets. Designed to meet stringent demands for precision, safety, and energy efficiency, these machines are set to empower sheet metal fabricators worldwide.

Built to Endure: Robust Engineering for Long-Term Reliability

Han's Laser press brakes are manufactured to surpass global operational challenges. Each machine undergoes rigorous testing and holds international certifications, including CE and KCS, ensuring compliance and durability for industrial applications.

Ultra-Rigid Frame for Unmatched Stability

Frames are precision-machined using imported CNC floor-type boring and milling machines. Through vibration aging and tempering treatments, the structure achieves exceptional fatigue and deformation resistance. Critical stress points—such as cylinder bases and throat areas—are reinforced to extend machine longevity.

Integrated Hydraulic System: Efficiency Meets Reliability

Featuring corrosion-resistant stainless steel tanks and optimized oil circuit design, Han's Laser hydraulic systems minimize valve clogging and maintenance needs. The HBD series, for example, reduces oil consumption by over 60% compared to conventional models. A large-inertia oil tank tray further enhances bending rigidity and system stability.

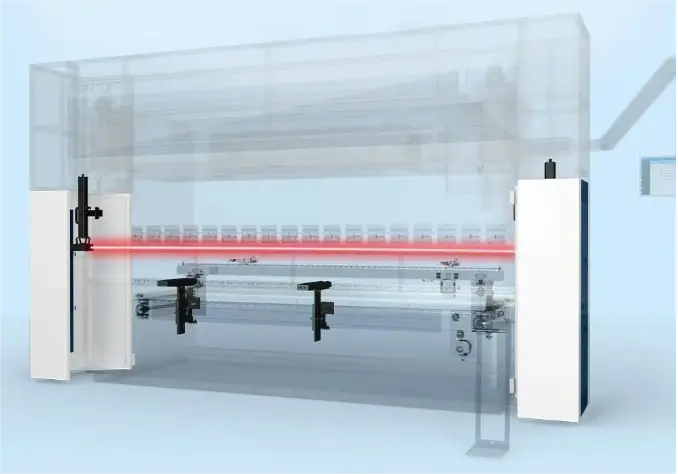

Safety-First Design for Uninterrupted Workflows

High-guard fencing, safety door interlock systems, and movable guide rail supports work together to create a secure production environment. Integrated safety light curtains maximize both operational space and personnel protection.

Product Line for Global Market Needs

HBS Series: Electro-Hydraulic Servo Press Brake – Precision Meets Value

Equipped with a closed-loop high-frequency hydraulic system, imported linear scales, and automatic mechanical crowning, the HBS Series ensures real-time feedback, dynamic compensation, and uniform bending angles even during long-stroke operations.

It delivers high accuracy and cost-efficiency, empowering customers to stay competitive in demanding international markets.

HBD Series: Dual Servo Hybrid Press Brake – Double Drive, Higher Efficiency

The HBD Series combines dual servo motors and proportional valve control to independently manage motion axes and optimize power output.

Compared with conventional hydraulic systems, it boosts processing efficiency by 30%, cuts energy consumption by 70%, and reduces noise levels.

This model provides a next-generation solution for energy-efficient, eco-friendly, and cost-effective metal forming.

HBE Series: All-Electric Press Brake – Green and Precise for Small Parts

Using servo motor direct drive with ball screw technology, the HBE Series eliminates hydraulic oil entirely, achieving clean and maintenance-free operation.

With a dynamic accuracy of ±0.01 mm, it’s ideal for 3C electronics, semiconductors, and other cleanroom-grade industries, meeting the dual pursuit of green manufacturing and micro-precision.

HBI Series: Multi-Sided Bending Center – Ideal for Box and Enclosure Fabrication

The HBI Series integrates a reinforced ram structure with a mortise-and-tenon tool holder, ensuring rigidity and durability.

Its dual-direction crowning compensation and multi-bearing layout counter deformation effectively, guaranteeing long-term accuracy in complex bending applications.

Automation: Expanding the Boundaries of Smart Manufacturing

Beyond individual press brake models, Han’s Laser is driving the evolution of automated bending solutions for smart and flexible production lines.

Robot Bending Cell

The integrated robotic bending unit enables full-process automation—from loading and positioning to bending and stacking—supporting 24/7 continuous operation.

It enhances consistency, reduces labor dependence, and boosts productivity, with flexible options for fixed or mobile robot configurations, tailored to diverse production needs.

3D Import and Auto Programming

With 3D model import, the system automatically detects bending parameters, simulates motion paths, and prevents collisions.

It generates optimized bending programs and can even produce laser nesting files, forming a seamless digital link between laser cutting and bending, greatly improving production efficiency and process coordination.

Empowering Global Fabrication with Innovation

Han's Laser continues to expand its global footprint with high-performance, eco-conscious, and intelligent bending solutions. By investing in R&D and aligning with worldwide industry trends, Han's Laser remains a trusted partner for sheet metal professionals seeking precision, sustainability, and automation.

Previous

Previous

LET’S TALK

LET’S TALK